Page 236 - Separation process engineering

P. 236

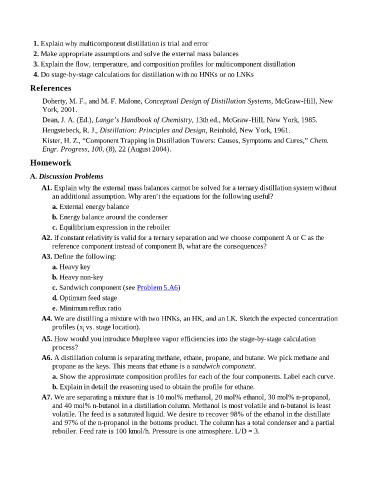

1. Explain why multicomponent distillation is trial and error

2. Make appropriate assumptions and solve the external mass balances

3. Explain the flow, temperature, and composition profiles for multicomponent distillation

4. Do stage-by-stage calculations for distillation with no HNKs or no LNKs

References

Doherty, M. F., and M. F. Malone, Conceptual Design of Distillation Systems, McGraw-Hill, New

York, 2001.

Dean, J. A. (Ed.), Lange’s Handbook of Chemistry, 13th ed., McGraw-Hill, New York, 1985.

Hengstebeck, R. J., Distillation: Principles and Design, Reinhold, New York, 1961.

Kister, H. Z., “Component Trapping in Distillation Towers: Causes, Symptoms and Cures,” Chem.

Engr. Progress, 100, (8), 22 (August 2004).

Homework

A. Discussion Problems

A1. Explain why the external mass balances cannot be solved for a ternary distillation system without

an additional assumption. Why aren’t the equations for the following useful?

a. External energy balance

b. Energy balance around the condenser

c. Equilibrium expression in the reboiler

A2. If constant relativity is valid for a ternary separation and we choose component A or C as the

reference component instead of component B, what are the consequences?

A3. Define the following:

a. Heavy key

b. Heavy non-key

c. Sandwich component (see Problem 5.A6)

d. Optimum feed stage

e. Minimum reflux ratio

A4. We are distilling a mixture with two HNKs, an HK, and an LK. Sketch the expected concentration

profiles (x vs. stage location).

i

A5. How would you introduce Murphree vapor efficiencies into the stage-by-stage calculation

process?

A6. A distillation column is separating methane, ethane, propane, and butane. We pick methane and

propane as the keys. This means that ethane is a sandwich component.

a. Show the approximate composition profiles for each of the four components. Label each curve.

b. Explain in detail the reasoning used to obtain the profile for ethane.

A7. We are separating a mixture that is 10 mol% methanol, 20 mol% ethanol, 30 mol% n-propanol,

and 40 mol% n-butanol in a distillation column. Methanol is most volatile and n-butanol is least

volatile. The feed is a saturated liquid. We desire to recover 98% of the ethanol in the distillate

and 97% of the n-propanol in the bottoms product. The column has a total condenser and a partial

reboiler. Feed rate is 100 kmol/h. Pressure is one atmosphere. L/D = 3.