Page 15 - Separation process principles 2

P. 15

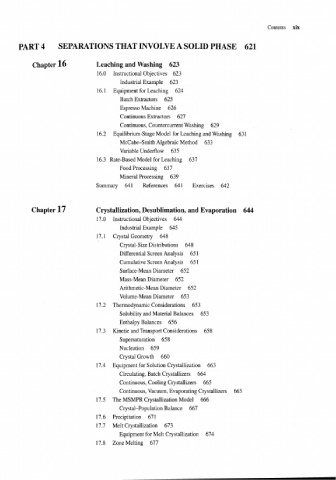

Contents xix

PART 4 SEPARATIONS THAT INVOLVE A SOLID PHASE 621

Chapter 16 Leaching and Washing 623

16.0 Instructional Objectives 623

Industrial Example 623

16.1 Equipment for Leaching 624

Batch Extractors 625

Espresso Machine 626

Continuous Extractors 627

Continuous, Countercurrent Washing 629

16.2 Equilibrium-Stage Model for Leaching and Washing 631

McCabe-Smith Algebraic Method 633

Variable Underflow 635

16.3 Rate-Based Model for Leaching 637

Food Processing 637

Mineral Processing 639

Summary 641 References 641 Exercises 642

Chapter 17 Crystallization, Desublimation, and Evaporation 644

17.0 Instructional Objectives 644

Industrial Example 645

17.1 Crystal Geometry 648

Crystal-Size Distributions 648

Differential Screen Analysis 65 1

Cumulative Screen Analysis 65 1

Surface-Mean Diameter 652

Mass-Mean Diameter 652

Arithmetic-Mean Diameter 652

Volume-Mean Diameter 653

17.2 Thermodynamic Considerations 653

Solubility and Material Balances 653

Enthalpy Balances 656

17.3 Kinetic and Transport Considerations 658

Supersaturation 658

Nucleation 659

Crystal Growth 660

17.4 Equipment for Solution Crystallization 663

Circulating, Batch Crystallizers 664

Continuous, Cooling Crystallizers 665

Continuous, Vacuum, Evaporating Crystallizers 665

17.5 The MSMPR Crystallization Model 666

Crystal-Population Balance 667

17.6 Precipitation 671

17.7 Meltcrystallization 673

Equipment for Melt Crystallization 674

17.8 Zone Melting 677