Page 58 - Separation process principles 2

P. 58

Summary 23

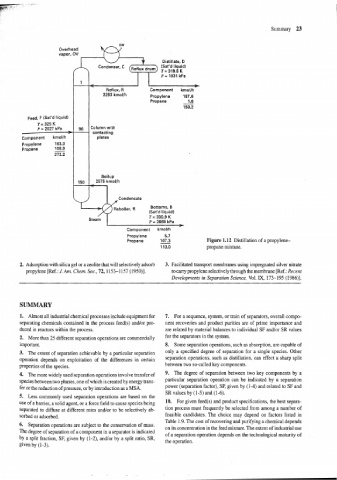

Overhead

vapor, OV

$. Distillate, D

Condenser, C @eflux drum) (Sat'd liquid)

T= 319.5 K

P = 1931 kPa

1 - >

Reflux, R Component kmollh

2293 kmollh Propylene 157.6

Propane 1.6

159.2

Feed, F (Sat'd liquid)

K

~=325

p = 2027 kPa 90 Column with

contacting

L

component kmollh plates

propylene 163.3

propane -

108.9

272.2

Boilup

150 - 2575 kmollh

Condensate

Bottoms, B

(Sat'd liquid)

T = 330.9 K

P = 2069 kPa *

Component kmollh

Propylene 5.7

Propane - Figure 1.12 Distillation of a propylene-

107.3

113.0 propane mixture.

2. Adsorption with silica gel or a zeolite that will selectively adsorb 3. Facilitated transport membranes using impregnated silver nitrate

propylene [Ref.: J. Am. Chem. Soc., 72,1153-1157 (1950)l. to cany propylene selectively through the membrane [Ref.: Recent

Developments in Separation Science, Vol. IX, 173-195 (1986)l.

SUMMARY

1. Almost all industrial chemical processes include equipment for 7. For a sequence, system, or train of separators, overall compo-

separating chemicals contained in the process feed(s) and/or pro- nent recoveries and product purities are of prime importance and

duced in reactors within the process. are related by material balances to individual SF and/or SR values

2. More than 25 different separation operations are conlrnercially for the separators in the system.

important. 8. Some separation operations, such as absorption, are capable of

3. The extent of separation achievable by a particular separation only a specified degree of separation for a single species. Other

operation depends on exploitation of the differences in certain separation operations, such as distillation, can effect a sharp split

properties of the species. between two so-called key components.

4. The more widely used separation operations involve transfer of 9. The degree of separation between two key components by a

species between two phases, one of which is created by energy trans- particular separation operation can be indicated by a separation

fer or the reduction of pressure, or by introduction as a MSA. power (separation factor), SP, given by (1-4) and related to SF and

SR values by (1-5) and (1-6).

5. Less commonly used separation operations are based on the

use of a barrier, a solid agent, or a force field to cause species being 10. For given feed(s) and product specifications, the best separa-

separated to diffuse at different rates and/or to be selectively ab- tion process must frequently be selected from among a number of

sorbed or adsorbed. feasible candidates. The choice may depend on factors listed in

Table 1.9. The cost of recovering and purifying a chemical depends

6. Separation operations are subject to the conservation of mass.

on its concentration in the feed mixture. The extent of industrial use

The degree of separation of a component in a separator is indicated

of a separation operation depends on the technological maturity of

by a split fraction, SF, given by (1-2), and/or by a split ratio, SR,

the operation.

given by (1-3).