Page 177 - Serious Incident Prevention How to Achieve and Sustain Accident-Free Operations in Your Plant or Company

P. 177

CH13pp141-152 4/10/02 12:51 PM Page 146

146 Serious Incident Prevention

the who, what, when, and why for reinforcing achievement of performance

milestones.

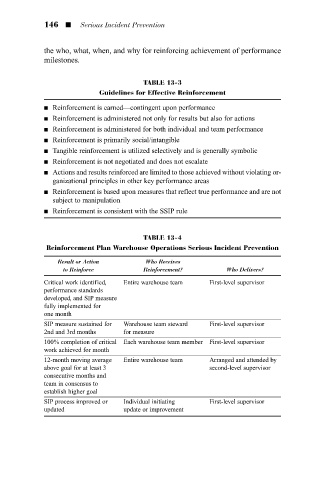

TABLE 13-3

Guidelines for Effective Reinforcement

Reinforcement is earned—contingent upon performance

Reinforcement is administered not only for results but also for actions

Reinforcement is administered for both individual and team performance

Reinforcement is primarily social/intangible

Tangible reinforcement is utilized selectively and is generally symbolic

Reinforcement is not negotiated and does not escalate

Actions and results reinforced are limited to those achieved without violating or-

ganizational principles in other key performance areas

Reinforcement is based upon measures that reflect true performance and are not

subject to manipulation

Reinforcement is consistent with the SSIP rule

TABLE 13-4

Reinforcement Plan Warehouse Operations Serious Incident Prevention

Result or Action Who Receives

to Reinforce Reinforcement? Who Delivers?

Critical work identified, Entire warehouse team First-level supervisor

performance standards

developed, and SIP measure

fully implemented for

one month

SIP measure sustained for Warehouse team steward First-level supervisor

2nd and 3rd months for measure

100% completion of critical Each warehouse team member First-level supervisor

work achieved for month

12-month moving average Entire warehouse team Arranged and attended by

above goal for at least 3 second-level supervisor

consecutive months and

team in consensus to

establish higher goal

SIP process improved or Individual initiating First-level supervisor

updated update or improvement