Page 109 - Shale Shakers Drilling Fluid Systems

P. 109

92 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

HOW A SHALE SHAKER SCREENS FLUID

Shale shakers should remove as many drilled

solids and as little drilling fluid as possible. These

dual objectives require that cuttings (or drilled

solids) convey off the screen while simultaneously

separating and removing most of the drilling fluid

from the cuttings. Frequently, the only stated

objective of a shale shaker is to remove the

maximum quantity of drilled solids. Disregarding

the need to conserve as much drilling fluid as pos-

sible defeats the ultimate objective of reducing

drilling costs.

Cutting sizes greatly influence the quantity of

drilling fluid that tends to adhere to the solids. As

an extreme example, consider a golfball-size drilled

solid coated with drilling fluid. Even with a viscous

fluid, the volume of fluid would be very small

compared with the volume of the solid. If the sol-

ids are sand-sized, the fluid-film volume increases

as the solids surface area increases. For silt-size FIGURE 2-1

or ultra-fine solids, the volume of liquid coating

the solids may even be larger than the solids vol-

ume. More drilling fluid returns to the system

when very coarse screens are used than when

screens as fine as 200 mesh are used.

Drilling fluid is a Theologically complex system.

At the bottom of the hole, faster drilling is pos-

sible if the fluid has a low viscosity. In the annu-

lus, drilled solids are transported better if the fluid

has a high viscosity. When the flow stops, a gel

structure slowly builds to prevent cuttings or weight-

ing agents from settling. Drilling fluid is usually

constructed to perform these functions. This means

that the fluid viscosity depends on the history and

shear within the fluid. Typically, low-shear-rate

viscosities of drilling fluids range from 300 to 400

centipoise up to 1000 to 1500 centipoise. As the

shear rate (or usually the velocity) increases, drill-

ing fluid viscosity decreases. Even with a low-

shear-rate viscosity of 1500 centipoise, the plastic

viscosity (or high-shear-rate viscosity) could be as

low as 10 centipoise.

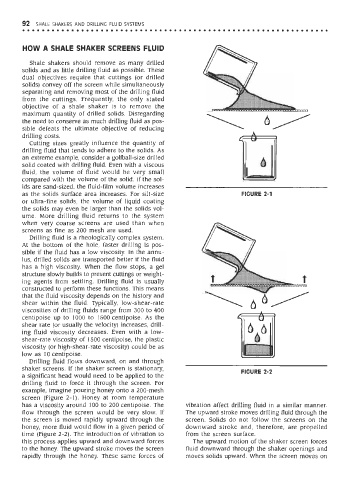

Drilling fluid flows downward, on and through

shaker screens. If the shaker screen is stationary, FIGURE 2-2

a significant head would need to be applied to the

drilling fluid to force it through the screen. For

example, imagine pouring honey onto a 200-mesh

screen (Figure 2-1). Honey at room temperature

has a viscosity around 100 to 200 centipoise. The vibration affect drilling fluid in a similar manner.

flow through the screen would be very slow. If The upward stroke moves drilling fluid through the

the screen is moved rapidly upward through the screen. Solids do not follow the screens on the

honey, more fluid would flow in a given period of downward stroke and, therefore, are propelled

time (Figure 2-2). The introduction of vibration to from the screen surface.

this process applies upward and downward forces The upward motion of the shaker screen forces

to the honey. The upward stroke moves the screen fluid downward through the shaker openings and

rapidly through the honey. These same forces of moves solids upward. When the screen moves on