Page 114 - Shale Shakers Drilling Fluid Systems

P. 114

CHAPTE R THRE E

Shale Shaker Design

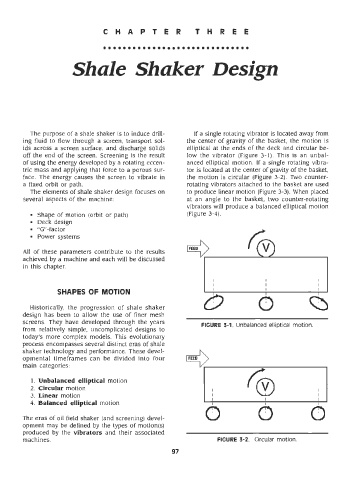

The purpose of a shale shaker is to induce drill- If a single rotating vibrator is located away from

ing fluid to flow through a screen, transport sol- the center of gravity of the basket, the motion is

ids across a screen surface, and discharge solids elliptical at the ends of the deck and circular be-

off the end of the screen. Screening is the result low the vibrator (Figure 3-1). This is an unbal-

of using the energy developed by a rotating eccen- anced elliptical motion. If a single rotating vibra-

tric mass and applying that force to a porous sur- tor is located at the center of gravity of the basket,

face. The energy causes the screen to vibrate in the motion is circular (Figure 3-2). Two counter-

a fixed orbit or path. rotating vibrators attached to the basket are used

The elements of shale shaker design focuses on to produce linear motion (Figure 3-3). When placed

several aspects of the machine: at an angle to the basket, two counter-rotating

vibrators will produce a balanced elliptical motion

• Shape of motion (orbit or path) (Figure 3-4).

• Deck design

• "G"-factor

• Power systems

All of these parameters contribute to the results

achieved by a machine and each will be discussed

in this chapter.

SHAPES OF MOTION

Historically, the progression of shale shaker

design has been to allow the use of finer mesh

screens. They have developed through the years FIGURE 3-1. Unbalanced elliptical motion.

from relatively simple, uncomplicated designs to

today's more complex models. This evolutionary

process encompasses several distinct eras of shale

shaker technology and performance. These devel-

opmental timeframes can be divided into four

main categories:

1. Unbalanced elliptical motion

2. Circular motion

3. Linear motion

4. Balanced elliptical motion

The eras of oil field shaker (and screening) devel-

opment may be defined by the types of motion(s)

produced by the vibrators and their associated

machines. FIGURE 3-2. Circular motion.

97