Page 115 - Shale Shakers Drilling Fluid Systems

P. 115

98 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

and mechanically reliable, but were generally lim-

ited to 20-mesh and coarser screens.

In an unbalanced elliptical motion shaker (Fig-

ure 3-1), the movement of the shaker deck/bas-

ket is accomplished by placing a single vibrator

system above the shaker deck. In other words, the

mechanical system of spinning counterweights (or

an elliptical-shaped drive shaft) is installed above

the center of gravity of the deck. The resulting

motion imparted to the bed is a combination of

elliptical and circular. Directly below the vibrator

the motion of the basket is circular, while at ei-

ther end of the deck the motion is elliptical.

The orientation of the major axes of the ellipses

formed at the feed end and solids discharge end

FIGURE 3-3. Linear motion.

of the basket has a major impact on solids con-

veyance. Specifically, it is desirable for the major

axis of the ellipsoidal trace to be directed toward

the solids discharge end. However, the orientation

of the major axis of the ellipse formed at the

solids discharge end is exactly the opposite; it is

directed backward toward the feed end. This dis-

charge end thrust orientation is undesirable since

it makes discharging solids from the shaker more

difficult (Figure 3-5). To assist in solids convey-

ance, the deck or last screen is tilted downward

(Figure 3-6), or the vibrator is moved to the dis-

charge end. Moving the vibrator toward the dis-

charge end significantly reduces the fluid capac-

ity and the screen life of the end screen. This also

reduces the residence time of the feed slurry on

the screening surface.

Early elliptical motion shale shakers used hook

strip screens that were manually tensioned. A

series of tension rails and tension bolt spring

assemblies were used to pull the screens tightly

over the support bars to ensure proper tightening.

Pretensioned screens and pretensioned screen

panels were not introduced until the 1970s and

even then were not commonly used on elliptical

motion units.

FIGURE 3-4. Balanced elliptical motion.

Unbalanced Elliptical Motion

Shale Shakers

In the 1930s, elliptical (unbalanced) shale

shakers were adapted to the oil field. These first

shakers originated from the mineral ore dressing

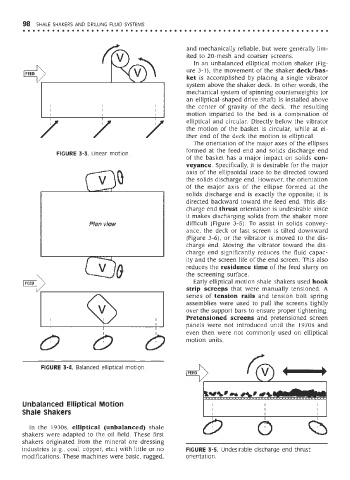

industries (e.g., coal, copper, etc.) with little or no FIGURE 3-5. Undesirable discharge end thrust

modifications. These machines were basic, rugged, orientation.