Page 117 - Shale Shakers Drilling Fluid Systems

P. 117

100 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

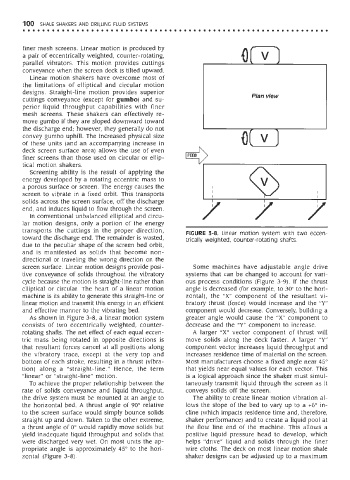

finer mesh screens. Linear motion is produced by

a pair of eccentrically weighted, counter-rotating,

parallel vibrators. This motion provides cuttings

conveyance when the screen deck is tilted upward.

Linear motion shakers have overcome most of

the limitations of elliptical and circular motion

designs. Straight-line motion provides superior

cuttings conveyance (except for gumbo) and su-

perior liquid throughput capabilities with finer

mesh screens. These shakers can effectively re-

move gumbo if they are sloped downward toward

the discharge end; however, they generally do not

convey gumbo uphill. The increased physical size

of these units (and an accompanying increase in

deck screen surface area) allows the use of even

finer screens than those used on circular or ellip-

tical motion shakers.

Screening ability is the result of applying the

energy developed by a rotating eccentric mass to

a porous surface or screen. The energy causes the

screen to vibrate in a fixed orbit. This transports

solids across the screen surface, off the discharge

end, and induces liquid to flow through the screen.

In conventional unbalanced elliptical and circu-

lar motion designs, only a portion of the energy

transports the cuttings in the proper direction, FIGURE 3-8. Linear motion system with two eccen-

toward the discharge end. The remainder is wasted, trically weighted, counter-rotating shafts.

due to the peculiar shape of the screen bed orbit,

and is manifested as solids that become non-

directional or traveling the wrong direction on the

screen surface. Linear motion designs provide posi- Some machines have adjustable angle drive

tive conveyance of solids throughout the vibratory systems that can be changed to account for vari-

cycle because the motion is straight-line rather than ous process conditions (Figure 3-9). If the thrust

elliptical or circular. The heart of a linear motion angle is decreased (for example, to 30° to the hori-

machine is its ability to generate this straight-line or zontal), the "X" component of the resultant vi-

linear motion and transmit this energy in an efficient bratory thrust (force) would increase and the "Y"

and effective manner to the vibrating bed. component would decrease. Conversely, building a

As shown in Figure 3-8, a linear motion system greater angle would cause the "X" component to

consists of two eccentrically weighted, counter- decrease and the "Y" component to increase.

rotating shafts. The net effect of each equal eccen- A larger "X" vector component of thrust will

tric mass being rotated in opposite directions is move solids along the deck faster. A larger "Y"

that resultant forces cancel at all positions along component vector increases liquid throughput and

the vibratory trace, except at the very top and increases residence time of material on the screen.

bottom of each stroke, resulting in a thrust (vibra- Most manufacturers choose a fixed angle near 45°

tion) along a "straight-line." Hence, the term that yields near equal values for each vector. This

"linear" or "straight-line" motion. is a logical approach since the shaker must simul-

To achieve the proper relationship between the taneously transmit liquid through the screen as it

rate of solids conveyance and liquid throughput, conveys solids off the screen.

the drive system must be mounted at an angle to The ability to create linear motion vibration al-

the horizontal bed. A thrust angle of 90° relative lows the slope of the bed to vary up to a +6° in-

to the screen surface would simply bounce solids cline (which impacts residence time and, therefore,

straight up and down. Taken to the other extreme, shaker performance) and to create a liquid pool at

a thrust angle of 0° would rapidly move solids but the flow line end of the machine. This allows a

yield inadequate liquid throughput and solids that positive liquid pressure head to develop, which

were discharged very wet. On most units the ap- helps "drive" liquid and solids through the finer

propriate angle is approximately 45° to the hori- wire cloths. The deck on most linear motion shale

zontal (Figure 3-8). shaker designs can be adjusted up to a maximum