Page 174 - Shale Shakers Drilling Fluid Systems

P. 174

SOLIDS CONTROL EQUIPMENT 157

The entire assembly is rotated while increasing

the "G"-force on the solids, which accelerates set-

tling. The fluid moves with the outer cylinder of

the centrifuge so there is no shear within the fluid.

This is the reason that dilution fluid is normally

added to the input stream of a decanting centri-

fuge. The low-shear-rate viscosity of most drilling

fluids is increased to aid hole-cleaning and to pro-

vide weighting agent support. This low-shear-rate

viscosity elevation will also inhibit settling within

FIGURE 7-7. Tank for continuous removal of solid a centrifuge.

particles from a process liquid. To convey the solids out of the centrifuge, the

conveyor and bowl must rotate at slightly differ-

ent speeds. This is accomplished using a planetary

gearbox for belt drive centrifuges. Typically, the

entire assembly rotates in the same direction, but

the conveyor rotates at a slightly slower speed.

The conveyor moves the solids to the solids dis-

charge end and the liquid, or effluent, emptys out

of the weirs at the liquid discharge end.

To calculate the "G"-factor a centrifuge imparts

to solids, the formula is as follows:

FIGURE 7-8

where G is the ratio of the centripetal acceleration

of the bowl compared to the acceleration of grav-

ity. (Note, this is the same equation used to cal-

culate the "G"-factor of shale shaker vibrators.)

A centrifuge provides a method of increasing

the settling force on particles suspended in liquid.

The force depends on the mass of the particle and

not the chemical composition. Particles with the

same mass, whether they are barite, low-gravity

solids, gold, iron, or silver, will settle at the same

rate. Centrifuges are able to separate solids above

and below the 2- to 10-micron size range. In

weighted drilling fluids, centrifuges are capable of

eliminating very small particles that can cause

dramatic increases in both the low- and high-

shear-rate viscosities. In unweighted drilling fluid

FIGURE 7-9

they are used as "super desilters."

Types of Centrifuges

Two types of centrifuges are generally used

to process drilling fluids: decanters and rotary

mud separators.

A decanting centrifuge (Figure 7-10 or 7-11) has

a bowl that rotates at a high speed (from about

1200 to 3600 rpm). The solids are thrown to the

wall of the bowl with a force that depends on their

mass. A conveyer transports the solids along the

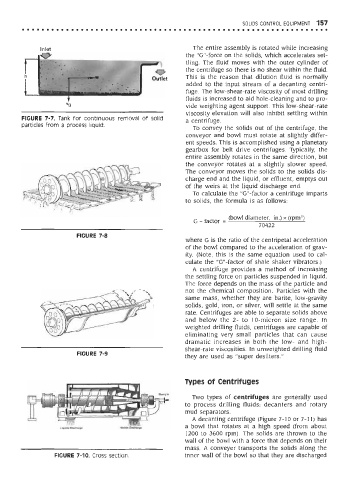

FIGURE 7-10. Cross section. inner wall of the bowl so that they are discharged