Page 176 - Shale Shakers Drilling Fluid Systems

P. 176

SOLIDS CONTROL EQUIPMENT 159

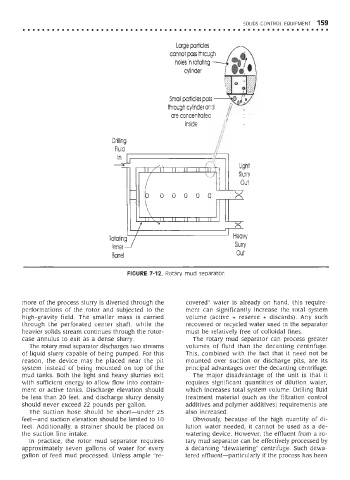

FIGURE 7-12. Rotary mud separator.

more of the process slurry is diverted through the covered" water is already on hand, this require-

performations of the rotor and subjected to the ment can significantly increase the total system

high-gravity field. The smaller mass is carried volume (active + reserve + discards). Any such

through the perforated center shaft, while the recovered or recycled water used in the separator

heavier solids stream continues through the rotor- must be relatively free of colloidal fines.

case annulus to exit as a dense slurry. The rotary mud separator can process greater

The rotary mud separator discharges two streams volumes of fluid than the decanting centrifuge.

of liquid slurry capable of being pumped. For this This, combined with the fact that it need not be

reason, the device may be placed near the pit mounted over suction or discharge pits, are its

system instead of being mounted on top of the principal advantages over the decanting centrifuge.

mud tanks. Both the light and heavy slurries exit The major disadvantage of the unit is that it

with sufficient energy to allow flow into contain- requires significant quantities of dilution water,

ment or active tanks. Discharge elevation should which increases total system volume. Drilling fluid

be less than 20 feet, and discharge slurry density treatment material (such as the filtration control

should never exceed 22 pounds per gallon. additives and polymer additives) requirements are

The suction hose should be short—under 25 also increased.

feet—and suction elevation should be limited to 10 Obviously, because of the high quantity of di-

feet. Additionally, a strainer should be placed on lution water needed, it cannot be used as a de-

the suction line intake. watering device. However, the effluent from a ro-

In practice, the rotor mud separator requires tary mud separator can be effectively processed by

approximately seven gallons of water for every a decanting "dewatering" centrifuge. Such dewa-

gallon of feed mud processed. Unless ample "re- tered effluent—particularly if the process has been