Page 175 - Shale Shakers Drilling Fluid Systems

P. 175

158 SHALE SHAKERS AND DRILLING FLUID SYSTEMS

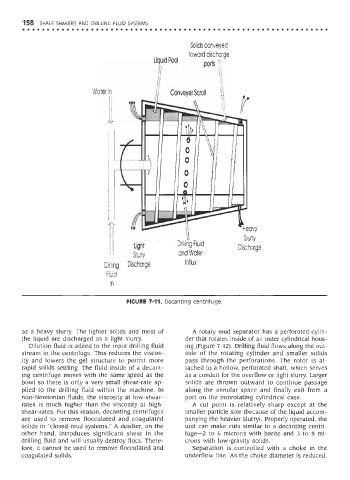

FIGURE 7-11. Decanting centrifuge.

as a heavy slurry. The lighter solids and most of A rotary mud separator has a perforated cylin-

the liquid are discharged as a light slurry. der that rotates inside of an outer cylindrical hous-

Dilution fluid is added to the input drilling fluid ing (Figure 7-12). Drilling fluid flows along the out-

stream in the centrifuge. This reduces the viscos- side of the rotating cylinder and smaller solids

ity and lowers the gel structure to permit more pass through the perforations. The rotor is at-

rapid solids settling. The fluid inside of a decant- tached to a hollow, perforated shaft, which serves

ing centrifuge moves with the same speed as the as a conduit for the overflow or light slurry. Larger

bowl so there is only a very small shear-rate ap- solids are thrown outward to continue passage

plied to the drilling fluid within the machine. In along the annular space and finally exit from a

non-Newtonian fluids, the viscosity at low-shear- port on the nonrotating cylindrical case.

rates is much higher than the viscosity at high- A cut point is relatively sharp except at the

shear-rates. For this reason, decanting centrifuges smaller particle size (because of the liquid accom-

are used to remove flocculated and coagulated panying the heavier slurry). Properly operated, the

solids in "closed-mud systems." A desilter, on the unit can make cuts similar to a decanting centri-

other hand, introduces significant shear in the fuge—2 to 6 microns with barite and 3 to 8 mi-

drilling fluid and will usually destroy floes. There- crons with low-gravity solids.

fore, it cannot be used to remove flocculated and Separation is controlled with a choke in the

coagulated solids. underflow line. As the choke diameter is reduced,