Page 285 - Shigley's Mechanical Engineering Design

P. 285

bud29281_ch05_212-264.qxd 12/7/09 7:23PM Page 260 ntt G4 Mac OS 9.2:Desktop Folder:MHDQ196/Budynas:

260 Mechanical Engineering Design

5–56* Build upon the results of Probs. 3–84 and 3–87 to compare the use of a low-strength, ductile mate-

rial (1018 CD) in which the stress-concentration factor can be ignored to a high-strength but more

brittle material (4140 Q&T @ 400°F) in which the stress-concentration factor should be included.

For each case, determine the factor of safety for yielding using the distortion-energy theory.

5–57 Design the lever arm CD of Fig. 5–16 by specifying a suitable size and material.

5–58 A spherical pressure vessel is formed of 16-gauge (0.0625-in) cold-drawn AISI 1020 sheet steel.

If the vessel has a diameter of 15 in, use the distortion-energy theory to estimate the pressure

necessary to initiate yielding. What is the estimated bursting pressure?

5–59 This problem illustrates that the strength of a machine part can sometimes be measured in units

other than those of force or moment. For example, the maximum speed that a flywheel can reach

without yielding or fracturing is a measure of its strength. In this problem you have a rotating ring

made of hot-forgedAISI 1020 steel; the ring has a 6-in inside diameter and a 10-in outside diameter

and is 1.5 in thick. Using the distortion-energy theory, determine the speed in revolutions per

minute that would cause the ring to yield. At what radius would yielding begin? [Note: The maxi-

mum radial stress occurs at r = (r o r i ) 1/2 ; see Eq. (3–55).]

5–60 A light pressure vessel is made of 2024-T3 aluminum alloy tubing with suitable end closures.

1

This cylinder has a 3 -in OD, a 0.065-in wall thickness, and ν = 0.334. The purchase order spec-

2

ifies a minimum yield strength of 46 kpsi. Using the distortion-energy theory, determine the factor

of safety if the pressure-release valve is set at 500 psi.

5–61 A cold-drawn AISI 1015 steel tube is 300 mm OD by 200 mm ID and is to be subjected to an

external pressure caused by a shrink fit. Using the distortion-energy theory, determine the maxi-

mum pressure that would cause the material of the tube to yield.

5–62 What speed would cause fracture of the ring of Prob. 5–59 if it were made of grade 30 cast iron?

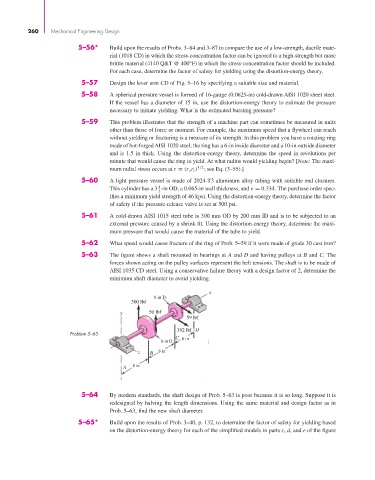

5–63 The figure shows a shaft mounted in bearings at A and D and having pulleys at B and C. The

forces shown acting on the pulley surfaces represent the belt tensions. The shaft is to be made of

AISI 1035 CD steel. Using a conservative failure theory with a design factor of 2, determine the

minimum shaft diameter to avoid yielding.

x

6-in D.

300 lbf

y 50 lbf

59 lbf

392 lbf D

Problem 5–63

C 6 in

8-in D.

z B 8 in

A 8 in

5–64 By modern standards, the shaft design of Prob. 5–63 is poor because it is so long. Suppose it is

redesigned by halving the length dimensions. Using the same material and design factor as in

Prob. 5–63, find the new shaft diameter.

5–65* Build upon the results of Prob. 3–40, p. 132, to determine the factor of safety for yielding based

on the distortion-energy theory for each of the simplified models in parts c, d, and e of the figure