Page 282 - Shigley's Mechanical Engineering Design

P. 282

bud29281_ch05_212-264.qxd 11/27/2009 9:06 pm Page 257 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Failures Resulting from Static Loading 257

5–3 Repeat Prob. 5–1 for a bar of AISI 1030 hot-rolled steel and:

(a) σ x = 25 kpsi, σ y = 15 kpsi

(b) σ x = 15 kpsi, σ y =−15 kpsi

(c) σ x = 20 kpsi, τ xy =−10 kpsi

(d) σ x =−12 kpsi,σ y = 15 kpsi, τ xy =−9 kpsi

(e) σ x =−24 kpsi, σ y =−24 kpsi,τ xy =−15 kpsi

5–4 Repeat Prob. 5–1 for a bar of AISI 1015 cold-drawn steel with the following principal stresses

obtained from Eq. (3–13):

(a) σ A = 30 kpsi, σ B = 30 kpsi

(b) σ A = 30 kpsi, σ B =−30 kpsi

(c) σ A = 30 kpsi, σ B = 15 kpsi

(d) σ A =−30 kpsi, σ B =−15 kpsi

(e) σ A =−50 kpsi, σ B = 10 kpsi

5–5 Repeat Prob. 5–1 by first plotting the failure loci in the σ A ,σ B plane to scale; then, for each stress

state, plot the load line and by graphical measurement estimate the factors of safety.

5–6 Repeat Prob. 5–3 by first plotting the failure loci in the σ A ,σ B plane to scale; then, for each stress

state, plot the load line and by graphical measurement estimate the factors of safety.

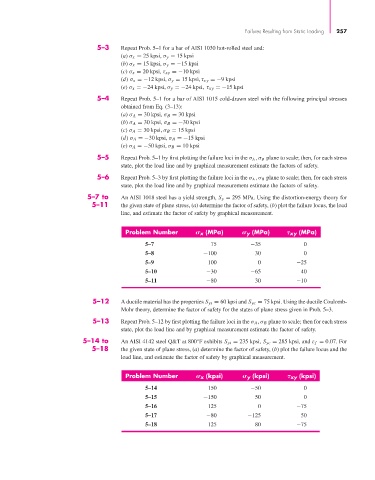

5–7 to An AISI 1018 steel has a yield strength, S y = 295 MPa. Using the distortion-energy theory for

5–11 the given state of plane stress, (a) determine the factor of safety, (b) plot the failure locus, the load

line, and estimate the factor of safety by graphical measurement.

Problem Number S x (MPa) S y (MPa) T xy (MPa)

5–7 75 −35 0

5–8 −100 30 0

5–9 100 0 −25

5–10 −30 −65 40

5–11 −80 30 −10

5–12 A ductile material has the properties S yt = 60 kpsi and S yc = 75 kpsi. Using the ductile Coulomb-

Mohr theory, determine the factor of safety for the states of plane stress given in Prob. 5–3.

5–13 Repeat Prob. 5–12 by first plotting the failure loci in the σ A , σ B plane to scale; then for each stress

state, plot the load line and by graphical measurement estimate the factor of safety.

5–14 to An AISI 4142 steel Q&T at 800°F exhibits S yt = 235 kpsi, S yc = 285 kpsi, and ε f = 0.07. For

5–18 the given state of plane stress, (a) determine the factor of safety, (b) plot the failure locus and the

load line, and estimate the factor of safety by graphical measurement.

Problem Number S x (kpsi) S y (kpsi) T xy (kpsi)

5–14 150 −50 0

5–15 −150 50 0

5–16 125 0 −75

5–17 −80 −125 50

5–18 125 80 −75