Page 357 - Shigley's Mechanical Engineering Design

P. 357

bud29281_ch06_265-357.qxd 12/02/2009 6:49 pm Page 332 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

332 Mechanical Engineering Design

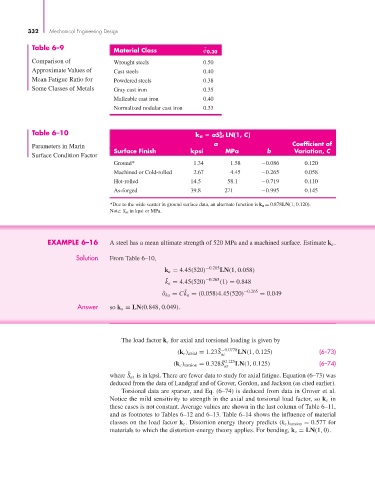

Table 6–9

Material Class φ 0.30

Comparison of Wrought steels 0.50

Approximate Values of Cast steels 0.40

Mean Fatigue Ratio for Powdered steels 0.38

Some Classes of Metals Gray cast iron 0.35

Malleable cast iron 0.40

Normalized nodular cast iron 0.33

Table 6–10 k a aS ut LN(1, C)

b

Parameters in Marin a Coefficient of

Surface Finish kpsi MPa b Variation, C

Surface Condition Factor

Ground* 1.34 1.58 −0.086 0.120

Machined or Cold-rolled 2.67 4.45 −0.265 0.058

Hot-rolled 14.5 58.1 −0.719 0.110

As-forged 39.8 271 −0.995 0.145

*Due to the wide scatter in ground surface data, an alternate function is k a = 0.878LN(1, 0.120).

Note: S ut in kpsi or MPa.

EXAMPLE 6–16 A steel has a mean ultimate strength of 520 MPa and a machined surface. Estimate k a .

Solution From Table 6–10,

k a = 4.45(520) −0.265 LN(1, 0.058)

¯

k a = 4.45(520) −0.265 (1) = 0.848

ˆ σ ka = Ck a = (0.058)4.45(520) −0.265 = 0.049

¯

Answer so k a = LN(0.848, 0.049).

The load factor k c for axial and torsional loading is given by

−0.0778

(k c ) axial = 1.23S ¯ ut LN(1, 0.125) (6–73)

0.125

(k c ) torsion = 0.328S ¯ ut LN(1, 0.125) (6–74)

where S ut is in kpsi. There are fewer data to study for axial fatigue. Equation (6–73) was

¯

deduced from the data of Landgraf and of Grover, Gordon, and Jackson (as cited earlier).

Torsional data are sparser, and Eq. (6–74) is deduced from data in Grover et al.

Notice the mild sensitivity to strength in the axial and torsional load factor, so k c in

these cases is not constant. Average values are shown in the last column of Table 6–11,

and as footnotes to Tables 6–12 and 6–13. Table 6–14 shows the influence of material

classes on the load factor k c . Distortion energy theory predicts (k c ) torsion = 0.577 for

materials to which the distortion-energy theory applies. For bending, k c = LN(1, 0).