Page 358 - Shigley's Mechanical Engineering Design

P. 358

bud29281_ch06_265-357.qxd 12/10/2009 4:46 pm Page 333 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Fatigue Failure Resulting from Variable Loading 333

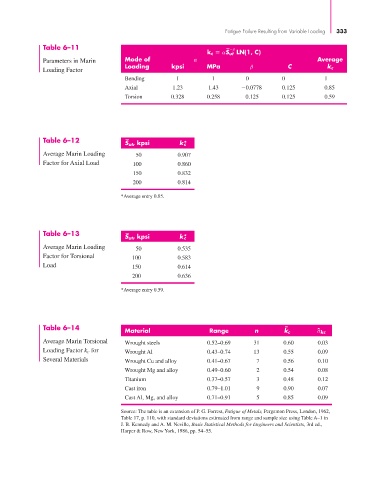

Table 6–11 −β

k c αS ut LN(1, C)

Parameters in Marin Mode of α Average

Loading kpsi MPa β C k c

Loading Factor

Bending 1 1 0 0 1

Axial 1.23 1.43 −0.0778 0.125 0.85

Torsion 0.328 0.258 0.125 0.125 0.59

Table 6–12 S ut, kpsi k* c

Average Marin Loading 50 0.907

Factor for Axial Load 100 0.860

150 0.832

200 0.814

*Average entry 0.85.

Table 6–13 S ut, kpsi k* c

Average Marin Loading 50 0.535

Factor for Torsional 100 0.583

Load 150 0.614

200 0.636

*Average entry 0.59.

Table 6–14 ¯

Material Range n k c σ

ˆ kc

Average Marin Torsional Wrought steels 0.52–0.69 31 0.60 0.03

Loading Factor k c for Wrought Al 0.43–0.74 13 0.55 0.09

Several Materials Wrought Cu and alloy 0.41–0.67 7 0.56 0.10

Wrought Mg and alloy 0.49–0.60 2 0.54 0.08

Titanium 0.37–0.57 3 0.48 0.12

Cast iron 0.79–1.01 9 0.90 0.07

Cast Al, Mg, and alloy 0.71–0.91 5 0.85 0.09

Source: The table is an extension of P. G. Forrest, Fatigue of Metals, Pergamon Press, London, 1962,

Table 17, p. 110, with standard deviations estimated from range and sample size using Table A–1 in

J. B. Kennedy and A. M. Neville, Basic Statistical Methods for Engineers and Scientists, 3rd ed.,

Harper & Row, New York, 1986, pp. 54–55.