Page 377 - Shigley's Mechanical Engineering Design

P. 377

bud29281_ch06_265-357.qxd 12/02/2009 6:49 pm Page 352 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

352 Mechanical Engineering Design

T

3

16

T

3

4

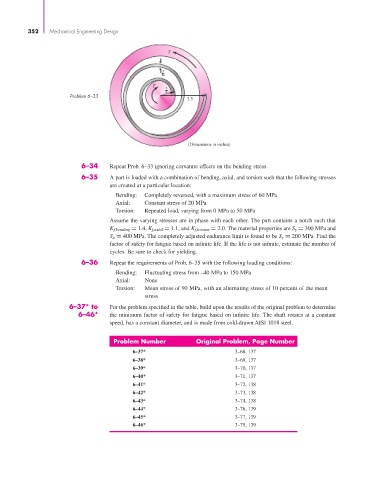

Problem 6–33

2.5

(Dimensions in inches)

6–34 Repeat Prob. 6–33 ignoring curvature effects on the bending stress.

6–35 A part is loaded with a combination of bending, axial, and torsion such that the following stresses

are created at a particular location:

Bending: Completely reversed, with a maximum stress of 60 MPa

Axial: Constant stress of 20 MPa

Torsion: Repeated load, varying from 0 MPa to 50 MPa

Assume the varying stresses are in phase with each other. The part contains a notch such that

K f,bending = 1.4, K f,axial = 1.1, and K f,torsion = 2.0. The material properties are S y = 300 MPa and

S u = 400 MPa. The completely adjusted endurance limit is found to be S e = 200 MPa. Find the

factor of safety for fatigue based on infinite life. If the life is not infinite, estimate the number of

cycles. Be sure to check for yielding.

6–36 Repeat the requirements of Prob. 6–35 with the following loading conditions:

Bending: Fluctuating stress from –40 MPa to 150 MPa

Axial: None

Torsion: Mean stress of 90 MPa, with an alternating stress of 10 percent of the mean

stress

6–37* to For the problem specified in the table, build upon the results of the original problem to determine

6–46* the minimum factor of safety for fatigue based on infinite life. The shaft rotates at a constant

speed, has a constant diameter, and is made from cold-drawn AISI 1018 steel.

Problem Number Original Problem, Page Number

6–37* 3–68, 137

6–38* 3–69, 137

6–39* 3–70, 137

6–40* 3–71, 137

6–41* 3–72, 138

6–42* 3–73, 138

6–43* 3–74, 138

6–44* 3–76, 139

6–45* 3–77, 139

6–46* 3–79, 139