Page 376 - Shigley's Mechanical Engineering Design

P. 376

bud29281_ch06_265-357.qxd 12/02/2009 6:49 pm Page 351 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

Fatigue Failure Resulting from Variable Loading 351

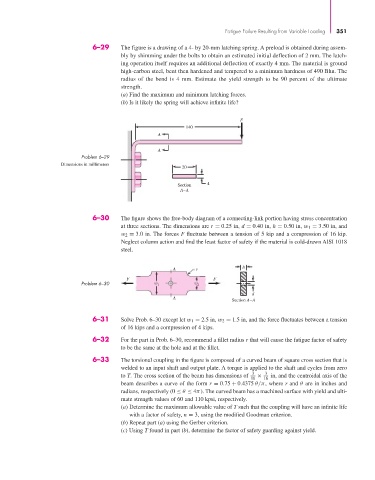

6–29 The figure is a drawing of a 4- by 20-mm latching spring. A preload is obtained during assem-

bly by shimming under the bolts to obtain an estimated initial deflection of 2 mm. The latch-

ing operation itself requires an additional deflection of exactly 4 mm. The material is ground

high-carbon steel, bent then hardened and tempered to a minimum hardness of 490 Bhn. The

radius of the bend is 4 mm. Estimate the yield strength to be 90 percent of the ultimate

strength.

(a) Find the maximum and minimum latching forces.

(b) Is it likely the spring will achieve infinite life?

F

140

A

A

Problem 6–29

Dimensions in millimeters

20

Section 4

A–A

6–30 The figure shows the free-body diagram of a connecting-link portion having stress concentration

at three sections. The dimensions are r = 0.25 in, d = 0.40 in, h = 0.50 in, w 1 = 3.50 in, and

w 2 = 3.0 in. The forces F fluctuate between a tension of 5 kip and a compression of 16 kip.

Neglect column action and find the least factor of safety if the material is cold-drawn AISI 1018

steel.

A r h

F F

Problem 6–30 w 1 w 2

d

A

Section A–A

6–31 Solve Prob. 6–30 except let w 1 = 2.5 in, w 2 = 1.5 in, and the force fluctuates between a tension

of 16 kips and a compression of 4 kips.

6–32 For the part in Prob. 6–30, recommend a fillet radius r that will cause the fatigue factor of safety

to be the same at the hole and at the fillet.

6–33 The torsional coupling in the figure is composed of a curved beam of square cross section that is

welded to an input shaft and output plate. A torque is applied to the shaft and cycles from zero

3 3

to T. The cross section of the beam has dimensions of × in, and the centroidal axis of the

16 16

beam describes a curve of the form r = 0.75 + 0.4375 θ/π, where r and θ are in inches and

radians, respectively (0 ≤ θ ≤ 4π). The curved beam has a machined surface with yield and ulti-

mate strength values of 60 and 110 kpsi, respectively.

(a) Determine the maximum allowable value of T such that the coupling will have an infinite life

with a factor of safety, n = 3, using the modified Goodman criterion.

(b) Repeat part (a) using the Gerber criterion.

(c) Using T found in part (b), determine the factor of safety guarding against yield.