Page 375 - Shigley's Mechanical Engineering Design

P. 375

bud29281_ch06_265-357.qxd 11/30/2009 4:24 pm Page 350 pinnacle s-171:Desktop Folder:Temp Work:Don't Delete (Jobs):MHDQ196/Budynas:

350 Mechanical Engineering Design

6–20 A bar of steel has the minimum properties S e = 40 kpsi, S y = 60 kpsi, and S ut = 80 kpsi. The

bar is subjected to a steady torsional stress of 15 kpsi and an alternating bending stress of 25 kpsi.

Find the factor of safety guarding against a static failure, and either the factor of safety guarding

against a fatigue failure or the expected life of the part. For the fatigue analysis use:

(a) Modified Goodman criterion.

(b) Gerber criterion.

(c) ASME-elliptic criterion.

6–21 Repeat Prob. 6–20 but with a steady torsional stress of 20 kpsi and an alternating bending stress

of 10 kpsi.

6–22 Repeat Prob. 6–20 but with a steady torsional stress of 15 kpsi, an alternating torsional stress of

10 kpsi, and an alternating bending stress of 12 kpsi.

6–23 Repeat Prob. 6–20 but with an alternating torsional stress of 30 kpsi.

6–24 Repeat Prob. 6–20 but with an alternating torsional stress of 15 kpsi and a steady bending stress

of 15 kpsi.

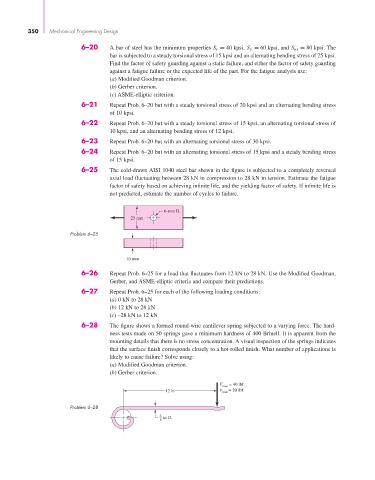

6–25 The cold-drawn AISI 1040 steel bar shown in the figure is subjected to a completely reversed

axial load fluctuating between 28 kN in compression to 28 kN in tension. Estimate the fatigue

factor of safety based on achieving infinite life, and the yielding factor of safety. If infinite life is

not predicted, estimate the number of cycles to failure.

6-mm D.

25 mm

Problem 6–25

10 mm

6–26 Repeat Prob. 6–25 for a load that fluctuates from 12 kN to 28 kN. Use the Modified Goodman,

Gerber, and ASME-elliptic criteria and compare their predictions.

6–27 Repeat Prob. 6–25 for each of the following loading conditions:

(a) 0 kN to 28 kN

(b) 12 kN to 28 kN

(c) –28 kN to 12 kN

6–28 The figure shows a formed round-wire cantilever spring subjected to a varying force. The hard-

ness tests made on 50 springs gave a minimum hardness of 400 Brinell. It is apparent from the

mounting details that there is no stress concentration. A visual inspection of the springs indicates

that the surface finish corresponds closely to a hot-rolled finish. What number of applications is

likely to cause failure? Solve using:

(a) Modified Goodman criterion.

(b) Gerber criterion.

F max = 40 lbf

12 in F min = 20 lbf

Problem 6–28

3 in D.

8