Page 387 - Shigley's Mechanical Engineering Design

P. 387

bud29281_ch07_358-408.qxd 12/8/09 12:52PM Page 362 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

362 Mechanical Engineering Design

Figure 7–1

A vertical worm-gear speed

reducer. (Courtesy of the

Cleveland Gear Company.)

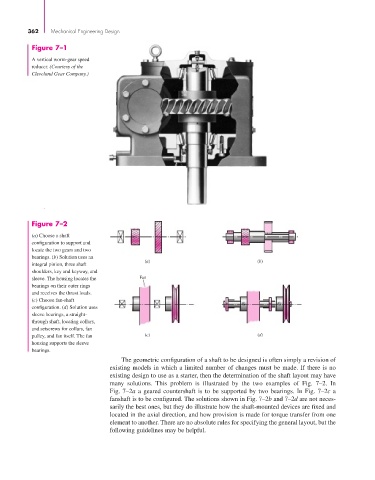

Figure 7–2

(a) Choose a shaft

configuration to support and

locate the two gears and two

bearings. (b) Solution uses an

(a) (b)

integral pinion, three shaft

shoulders, key and keyway, and

sleeve. The housing locates the Fan

bearings on their outer rings

and receives the thrust loads.

(c) Choose fan-shaft

configuration. (d) Solution uses

sleeve bearings, a straight-

through shaft, locating collars,

and setscrews for collars, fan

pulley, and fan itself. The fan (c) (d)

housing supports the sleeve

bearings.

The geometric configuration of a shaft to be designed is often simply a revision of

existing models in which a limited number of changes must be made. If there is no

existing design to use as a starter, then the determination of the shaft layout may have

many solutions. This problem is illustrated by the two examples of Fig. 7–2. In

Fig. 7–2a a geared countershaft is to be supported by two bearings. In Fig. 7–2c a

fanshaft is to be configured. The solutions shown in Fig. 7–2b and 7–2d are not neces-

sarily the best ones, but they do illustrate how the shaft-mounted devices are fixed and

located in the axial direction, and how provision is made for torque transfer from one

element to another. There are no absolute rules for specifying the general layout, but the

following guidelines may be helpful.