Page 389 - Shigley's Mechanical Engineering Design

P. 389

bud29281_ch07_358-408.qxd 12/8/09 12:52PM Page 364 ntt 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

364 Mechanical Engineering Design

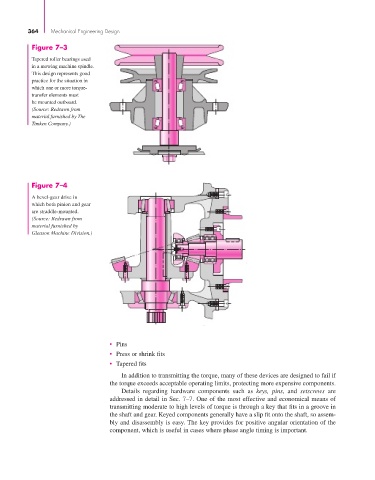

Figure 7–3

Tapered roller bearings used

in a mowing machine spindle.

This design represents good

practice for the situation in

which one or more torque-

transfer elements must

be mounted outboard.

(Source: Redrawn from

material furnished by The

Timken Company.)

Figure 7–4

A bevel-gear drive in

which both pinion and gear

are straddle-mounted.

(Source: Redrawn from

material furnished by

Gleason Machine Division.)

• Pins

• Press or shrink fits

• Tapered fits

In addition to transmitting the torque, many of these devices are designed to fail if

the torque exceeds acceptable operating limits, protecting more expensive components.

Details regarding hardware components such as keys, pins, and setscrews are

addressed in detail in Sec. 7–7. One of the most effective and economical means of

transmitting moderate to high levels of torque is through a key that fits in a groove in

the shaft and gear. Keyed components generally have a slip fit onto the shaft, so assem-

bly and disassembly is easy. The key provides for positive angular orientation of the

component, which is useful in cases where phase angle timing is important.