Page 536 - Shigley's Mechanical Engineering Design

P. 536

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 510 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

510 Mechanical Engineering Design

9–29 The permissible shear stress for the weldment illustrated is 20 kpsi. Estimate the load, F, that will

cause this stress in the weldment throat.

F

8 in

Problem 9–29

3 in

1 in

4

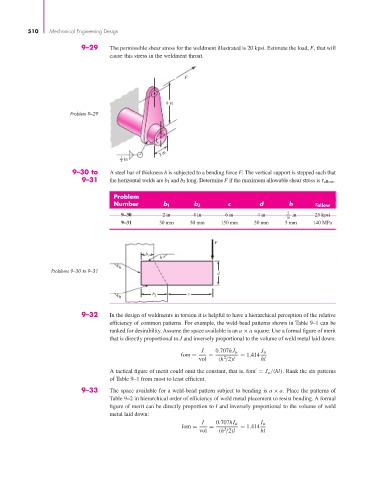

9–30 to A steel bar of thickness h is subjected to a bending force F. The vertical support is stepped such that

9–31 the horizontal welds are b 1 and b 2 long. Determine F if the maximum allowable shear stress is τ allow .

Problem

Number b 1 b 2 c d h allow

9–30 2 in 4 in 6 in 4 in 5 in 25 kpsi

16

9–31 30 mm 50 mm 150 mm 50 mm 5 mm 140 MPa

F

b 1 h

h

Problems 9–30 to 9–31 d

c

h b 2

9–32 In the design of weldments in torsion it is helpful to have a hierarchical perception of the relative

efficiency of common patterns. For example, the weld-bead patterns shown in Table 9–1 can be

ranked for desirability. Assume the space available is an a × a square. Use a formal figure of merit

that is directly proportional to J and inversely proportional to the volume of weld metal laid down:

J 0.707hJ u J u

fom = = = 1.414

vol (h /2)l hl

2

A tactical figure of merit could omit the constant, that is, fom = J u /(hl). Rank the six patterns

of Table 9–1 from most to least efficient.

9–33 The space available for a weld-bead pattern subject to bending is a × a. Place the patterns of

Table 9–2 in hierarchical order of efficiency of weld metal placement to resist bending. A formal

figure of merit can be directly proportion to I and inversely proportional to the volume of weld

metal laid down:

I 0.707hI u I u

fom = = = 1.414

vol (h /2)l hl

2