Page 531 - Shigley's Mechanical Engineering Design

P. 531

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 505 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Welding, Bonding, and the Design of Permanent Joints 505

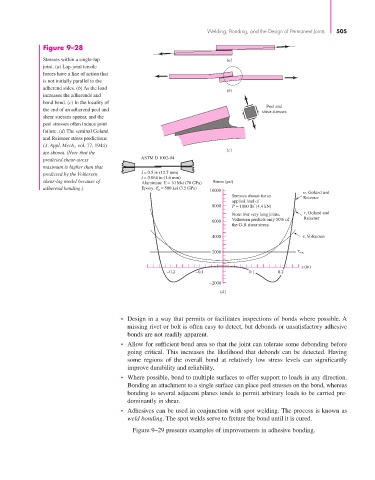

Figure 9–28

Stresses within a single-lap (a)

joint. (a) Lap-joint tensile

forces have a line of action that

is not initially parallel to the

adherend sides. (b) As the load

(b)

increases the adherends and

bond bend. (c) In the locality of

Peel and

the end of an adherend peel and

shear stresses

shear stresses appear, and the

peel stresses often induce joint

failure. (d) The seminal Goland

and Reissner stress predictions

(J. Appl. Mech., vol. 77, 1944)

(c)

are shown. (Note that the

predicted shear-stress ASTM D 1002-94

maximum is higher than that

predicted by the Volkersen l = 0.5 in (12.7 mm)

t = 0.064 in (1.6 mm)

shear-lag model because of Aluminum: E = 10 Msi (70 GPa) Stress (psi)

adherend bending.) Epoxy: E a = 500 ksi (3.5 GPa)

10000 , Goland and

Stresses shown for an Reissner

applied load of

8000 P = 1000 lbf (4.4 kN)

, Goland and

Note: For very long joints,

6000 Volkersen predicts only 50% of Reissner

the G-R shear stress.

4000 , Volkersen

2000 ave

x (in)

−0.2 −0.1 0.1 0.2

−2000

(d)

• Design in a way that permits or facilitates inspections of bonds where possible. A

missing rivet or bolt is often easy to detect, but debonds or unsatisfactory adhesive

bonds are not readily apparent.

• Allow for sufficient bond area so that the joint can tolerate some debonding before

going critical. This increases the likelihood that debonds can be detected. Having

some regions of the overall bond at relatively low stress levels can significantly

improve durability and reliability.

• Where possible, bond to multiple surfaces to offer support to loads in any direction.

Bonding an attachment to a single surface can place peel stresses on the bond, whereas

bonding to several adjacent planes tends to permit arbitrary loads to be carried pre-

dominantly in shear.

• Adhesives can be used in conjunction with spot welding. The process is known as

weld bonding. The spot welds serve to fixture the bond until it is cured.

Figure 9–29 presents examples of improvements in adhesive bonding.