Page 528 - Shigley's Mechanical Engineering Design

P. 528

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 502 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

502 Mechanical Engineering Design

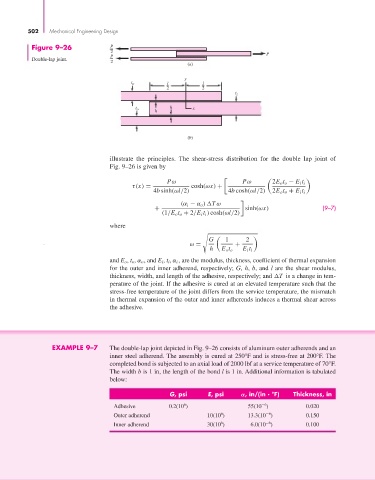

Figure 9–26 P

2 P

P

Double-lap joint.

2

(a)

y

t o l l

2 2

t i

t h x

o

h

(b)

illustrate the principles. The shear-stress distribution for the double lap joint of

Fig. 9–26 is given by

Pω Pω 2E o t o − E i t i

τ(x) = cosh(ωx) +

4b sinh(ωl/2) 4b cosh(ωl/2) 2E o t o + E i t i

(α i − α o ) Tω

+ sinh(ωx) (9–7)

(1/E o t o + 2/E i t i ) cosh(ωl/2)

where

G 1 2

ω = +

h E o t o E i t i

and E o , t o , α o , and E i , t i , α i , are the modulus, thickness, coefficient of thermal expansion

for the outer and inner adherend, respectively; G, h, b, and l are the shear modulus,

thickness, width, and length of the adhesive, respectively; and T is a change in tem-

perature of the joint. If the adhesive is cured at an elevated temperature such that the

stress-free temperature of the joint differs from the service temperature, the mismatch

in thermal expansion of the outer and inner adherends induces a thermal shear across

the adhesive.

EXAMPLE 9–7 The double-lap joint depicted in Fig. 9–26 consists of aluminum outer adherends and an

inner steel adherend. The assembly is cured at 250°F and is stress-free at 200°F. The

completed bond is subjected to an axial load of 2000 lbf at a service temperature of 70°F.

The width b is 1 in, the length of the bond l is 1 in. Additional information is tabulated

below:

G, psi E, psi , in/(in . °F) Thickness, in

−6

6

Adhesive 0.2(10 ) 55(10 ) 0.020

−6

6

Outer adherend 10(10 ) 13.3(10 ) 0.150

−6

6

Inner adherend 30(10 ) 6.0(10 ) 0.100