Page 526 - Shigley's Mechanical Engineering Design

P. 526

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 500 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

500 Mechanical Engineering Design

failure would be less critical) and nonstructural applications (of headliners, etc., for aes-

thetic purposes) are also of significant interest to the design engineer, providing cost-

effective means required for assembly of finished products. These include contact

adhesives, where a solution or emulsion containing an elastomeric adhesive is coated onto

both adherends, the solvent is allowed to evaporate, and then the two adherends are

brought into contact. Examples include rubber cement and adhesives used to bond lami-

nates to countertops. Pressure-sensitive adhesives are very low modulus elastomers that

deform easily under small pressures, permitting them to wet surfaces. When the substrate

and adhesive are brought into intimate contact, van der Waals forces are sufficient to main-

tain the contact and provide relatively durable bonds. Pressure-sensitive adhesives are nor-

mally purchased as tapes or labels for nonstructural applications, although there are also

double-sided foam tapes that can be used in semistructural applications. As the name

implies, hot melts become liquid when heated, wetting the surfaces and then cooling into

a solid polymer. These materials are increasingly applied in a wide array of engineering

applications by more sophisticated versions of the glue guns in popular use. Anaerobic

adhesives cure within narrow spaces deprived of oxygen; such materials have been widely

used in mechanical engineering applications to lock bolts or bearings in place. Cure in

other adhesives may be induced by exposure to ultraviolet light or electron beams, or it

may be catalyzed by certain materials that are ubiquitous on many surfaces, such as water.

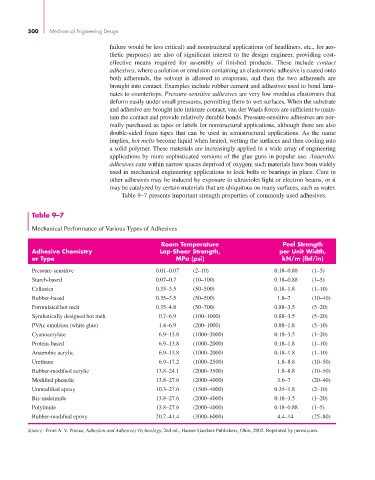

Table 9–7 presents important strength properties of commonly used adhesives.

Table 9–7

Mechanical Performance of Various Types of Adhesives

Room Temperature Peel Strength

Adhesive Chemistry Lap-Shear Strength, per Unit Width,

or Type MPa (psi) kN/m (lbf/in)

Pressure-sensitive 0.01–0.07 (2–10) 0.18–0.88 (1–5)

Starch-based 0.07–0.7 (10–100) 0.18–0.88 (1–5)

Cellosics 0.35–3.5 (50–500) 0.18–1.8 (1–10)

Rubber-based 0.35–3.5 (50–500) 1.8–7 (10–40)

Formulated hot melt 0.35–4.8 (50–700) 0.88–3.5 (5–20)

Synthetically designed hot melt 0.7–6.9 (100–1000) 0.88–3.5 (5–20)

PVAc emulsion (white glue) 1.4–6.9 (200–1000) 0.88–1.8 (5–10)

Cyanoacrylate 6.9–13.8 (1000–2000) 0.18–3.5 (1–20)

Protein-based 6.9–13.8 (1000–2000) 0.18–1.8 (1–10)

Anaerobic acrylic 6.9–13.8 (1000–2000) 0.18–1.8 (1–10)

Urethane 6.9–17.2 (1000–2500) 1.8–8.8 (10–50)

Rubber-modified acrylic 13.8–24.1 (2000–3500) 1.8–8.8 (10–50)

Modified phenolic 13.8–27.6 (2000–4000) 3.6–7 (20–40)

Unmodified epoxy 10.3–27.6 (1500–4000) 0.35–1.8 (2–10)

Bis-maleimide 13.8–27.6 (2000–4000) 0.18–3.5 (1–20)

Polyimide 13.8–27.6 (2000–4000) 0.18–0.88 (1–5)

Rubber-modified epoxy 20.7–41.4 (3000–6000) 4.4–14 (25–80)

Source: From A. V. Pocius, Adhesion and Adhesives Technology, 2nd ed., Hanser Gardner Publishers, Ohio, 2002. Reprinted by permission.