Page 522 - Shigley's Mechanical Engineering Design

P. 522

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 496 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

496 Mechanical Engineering Design

9–7 Fatigue Loading

The conventional methods will be provided here. In fatigue, the Gerber criterion is best;

however, you will find that the Goodman criterion is in common use. For the surface

factor of Eq. 6–19, an as-forged surface should always be assumed for weldments

unless a superior finish is specified and obtained.

Some examples of fatigue loading of welded joints follow.

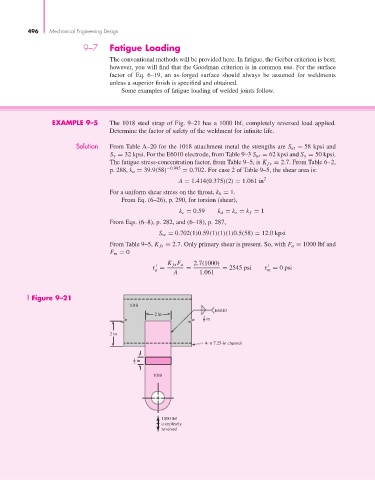

EXAMPLE 9–5 The 1018 steel strap of Fig. 9–21 has a 1000 lbf, completely reversed load applied.

Determine the factor of safety of the weldment for infinite life.

Solution From Table A–20 for the 1018 attachment metal the strengths are S ut = 58 kpsi and

S y = 32 kpsi. For the E6010 electrode, from Table 9–3 S ut = 62 kpsi and S y = 50 kpsi.

The fatigue stress-concentration factor, from Table 9–5, is K fs = 2.7. From Table 6–2,

p. 288, k a = 39.9(58) −0.995 = 0.702. For case 2 of Table 9–5, the shear area is:

A = 1.414(0.375)(2) = 1.061 in 2

For a uniform shear stress on the throat, k b = 1.

From Eq. (6–26), p. 290, for torsion (shear),

k c = 0.59 k d = k e = k f = 1

From Eqs. (6–8), p. 282, and (6–18), p. 287,

S se = 0.702(1)0.59(1)(1)(1)0.5(58) = 12.0 kpsi

From Table 9–5, K fs = 2.7. Only primary shear is present. So, with F a = 1000 lbf and

F m = 0

K fs F a 2.7(1000)

= 2545 psi τ = 0 psi

τ = =

a m

A 1.061

Figure 9–21

1018

E6010

2 in

3 in

8

2 in

4- × 7.25-in channel

1 in

2

1018

1000 lbf

completely

reversed