Page 535 - Shigley's Mechanical Engineering Design

P. 535

bud29281_ch09_475-516.qxd 12/16/2009 7:13 pm Page 509 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

Welding, Bonding, and the Design of Permanent Joints 509

F

h

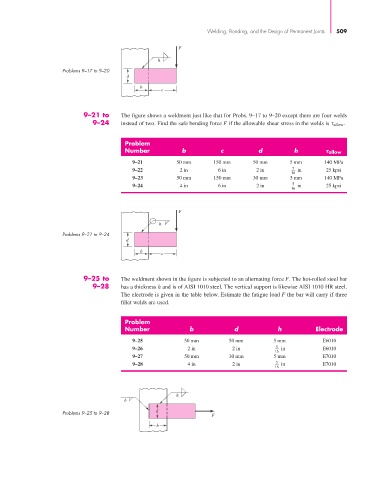

Problems 9–17 to 9–20

d

b

c

9–21 to The figure shows a weldment just like that for Probs. 9–17 to 9–20 except there are four welds

9–24 instead of two. Find the safe bending force F if the allowable shear stress in the welds is τ allow .

Problem

Number b c d h allow

9–21 50 mm 150 mm 50 mm 5 mm 140 MPa

9–22 2 in 6 in 2 in 5 in 25 kpsi

16

9–23 50 mm 150 mm 30 mm 5 mm 140 MPa

9–24 4 in 6 in 2 in 5 in 25 kpsi

16

F

h

Problems 9–21 to 9–24

d

b

c

9–25 to The weldment shown in the figure is subjected to an alternating force F. The hot-rolled steel bar

9–28 has a thickness h and is of AISI 1010 steel. The vertical support is likewise AISI 1010 HR steel.

The electrode is given in the table below. Estimate the fatigue load F the bar will carry if three

fillet welds are used.

Problem

Number b d h Electrode

9–25 50 mm 50 mm 5 mm E6010

9–26 2 in 2 in 5 in E6010

16

9–27 50 mm 30 mm 5 mm E7010

9–28 4 in 2 in 5 in E7010

16

h

h

Problems 9–25 to 9–28 d

F

b