Page 544 - Shigley's Mechanical Engineering Design

P. 544

bud29281_ch10_517-568.qxd 12/16/2009 7:14 pm Page 518 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

518 Mechanical Engineering Design

When a designer wants rigidity, negligible deflection is an acceptable approximation

as long as it does not compromise function. Flexibility is sometimes needed and is

often provided by metal bodies with cleverly controlled geometry. These bodies can

exhibit flexibility to the degree the designer seeks. Such flexibility can be linear or

nonlinear in relating deflection to load. These devices allow controlled application of

force or torque; the storing and release of energy can be another purpose. Flexibility

allows temporary distortion for access and the immediate restoration of function.

Because of machinery’s value to designers, springs have been intensively studied;

moreover, they are mass-produced (and therefore low cost), and ingenious configura-

tions have been found for a variety of desired applications. In this chapter we will

discuss the more frequently used types of springs, their necessary parametric rela-

tionships, and their design.

In general, springs may be classified as wire springs, flat springs, or special-

shaped springs, and there are variations within these divisions. Wire springs include

helical springs of round or square wire, made to resist and deflect under tensile, com-

pressive, or torsional loads. Flat springs include cantilever and elliptical types, wound

motor- or clock-type power springs, and flat spring washers, usually called Belleville

springs.

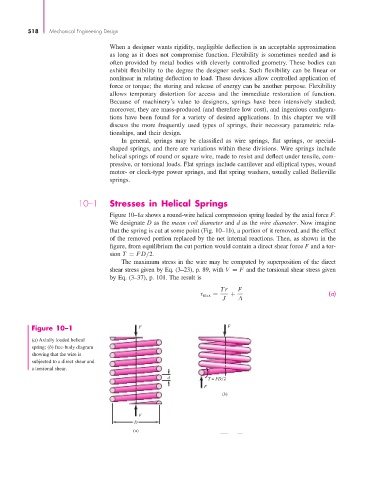

10–1 Stresses in Helical Springs

Figure 10–1a shows a round-wire helical compression spring loaded by the axial force F.

We designate D as the mean coil diameter and d as the wire diameter. Now imagine

that the spring is cut at some point (Fig. 10–1b), a portion of it removed, and the effect

of the removed portion replaced by the net internal reactions. Then, as shown in the

figure, from equilibrium the cut portion would contain a direct shear force F and a tor-

sion T = FD/2.

The maximum stress in the wire may be computed by superposition of the direct

shear stress given by Eq. (3–23), p. 89, with V = F and the torsional shear stress given

by Eq. (3–37), p. 101. The result is

Tr F

τ max = + (a)

J A

Figure 10–1 F F

(a) Axially loaded helical

spring; (b) free-body diagram

showing that the wire is

subjected to a direct shear and

a torsional shear.

d T = FD 2

F

(b)

F

D

(a)