Page 552 - Shigley's Mechanical Engineering Design

P. 552

bud29281_ch10_517-568.qxd 12/16/2009 7:14 pm Page 526 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

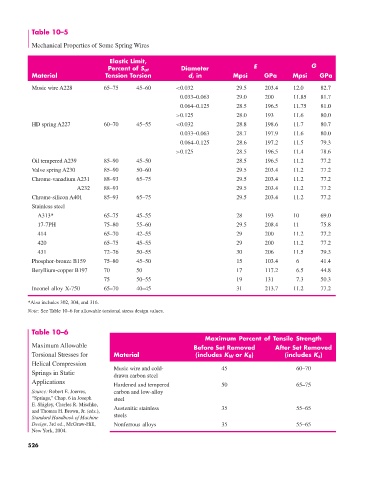

Table 10–5

Mechanical Properties of Some Spring Wires

Elastic Limit,

Percent of S ut Diameter E G

Material Tension Torsion d, in Mpsi GPa Mpsi GPa

Music wire A228 65–75 45–60 <0.032 29.5 203.4 12.0 82.7

0.033–0.063 29.0 200 11.85 81.7

0.064–0.125 28.5 196.5 11.75 81.0

>0.125 28.0 193 11.6 80.0

HD spring A227 60–70 45–55 <0.032 28.8 198.6 11.7 80.7

0.033–0.063 28.7 197.9 11.6 80.0

0.064–0.125 28.6 197.2 11.5 79.3

>0.125 28.5 196.5 11.4 78.6

Oil tempered A239 85–90 45–50 28.5 196.5 11.2 77.2

Valve spring A230 85–90 50–60 29.5 203.4 11.2 77.2

Chrome-vanadium A231 88–93 65–75 29.5 203.4 11.2 77.2

A232 88–93 29.5 203.4 11.2 77.2

Chrome-silicon A401 85–93 65–75 29.5 203.4 11.2 77.2

Stainless steel

A313* 65–75 45–55 28 193 10 69.0

17-7PH 75–80 55–60 29.5 208.4 11 75.8

414 65–70 42–55 29 200 11.2 77.2

420 65–75 45–55 29 200 11.2 77.2

431 72–76 50–55 30 206 11.5 79.3

Phosphor-bronze B159 75–80 45–50 15 103.4 6 41.4

Beryllium-copper B197 70 50 17 117.2 6.5 44.8

75 50–55 19 131 7.3 50.3

Inconel alloy X-750 65–70 40–45 31 213.7 11.2 77.2

*Also includes 302, 304, and 316.

Note: See Table 10–6 for allowable torsional stress design values.

Table 10–6

Maximum Percent of Tensile Strength

Maximum Allowable Before Set Removed After Set Removed

Torsional Stresses for Material (includes K W or K B) (includes K s)

Helical Compression

Springs in Static Music wire and cold- 45 60–70

drawn carbon steel

Applications Hardened and tempered 50 65–75

Source: Robert E. Joerres, carbon and low-alloy

“Springs,” Chap. 6 in Joseph steel

E. Shigley, Charles R. Mischke, Austenitic stainless 35 55–65

and Thomas H. Brown, Jr. (eds.),

Standard Handbook of Machine steels

Design, 3rd ed., McGraw-Hill, Nonferrous alloys 35 55–65

New York, 2004.

526