Page 146 - Six Sigma for electronics design and manufacturing

P. 146

Determining the Manufacturing Yield and Test Strategy

536

2/21

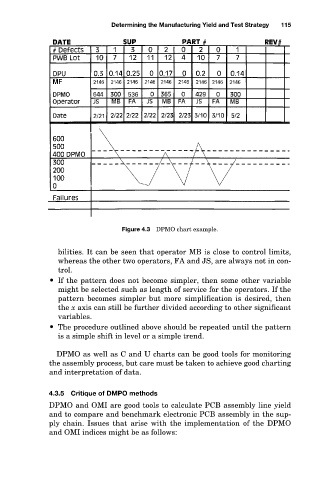

Figure 4.3 DPMO chart example. 115

bilities. It can be seen that operator MB is close to control limits,

whereas the other two operators, FA and JS, are always not in con-

trol.

If the pattern does not become simpler, then some other variable

might be selected such as length of service for the operators. If the

pattern becomes simpler but more simplification is desired, then

the x axis can still be further divided according to other significant

variables.

The procedure outlined above should be repeated until the pattern

is a simple shift in level or a simple trend.

DPMO as well as C and U charts can be good tools for monitoring

the assembly process, but care must be taken to achieve good charting

and interpretation of data.

4.3.5 Critique of DMPO methods

DPMO and OMI are good tools to calculate PCB assembly line yield

and to compare and benchmark electronic PCB assembly in the sup-

ply chain. Issues that arise with the implementation of the DPMO

and OMI indices might be as follows: