Page 141 - Six Sigma for electronics design and manufacturing

P. 141

Six Sigma for Electronics Design and Manufacturing

110

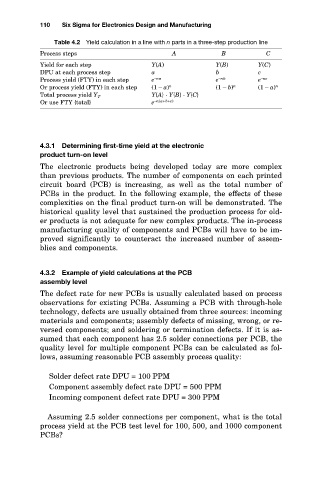

Table 4.2 Yield calculation in a line with n parts in a three-step production line

B

C

Process steps

A

Y(A)

Yield for each step

a

b

c

DPU at each process step

e

e

–na

–nc

e

Process yield (FTY) in each step

–nb

n

Or process yield (FTY) in each step

(1 – b)

(1 – a)

(1 – a)

Y{A}· Y{B}· Y{C}

Total process yield Y T

–n(a+b+c)

Or use FTY {total}

e

4.3.1 Determining first-time yield at the electronic Y(B) n Y(C) n

product turn-on level

The electronic products being developed today are more complex

than previous products. The number of components on each printed

circuit board (PCB) is increasing, as well as the total number of

PCBs in the product. In the following example, the effects of these

complexities on the final product turn-on will be demonstrated. The

historical quality level that sustained the production process for old-

er products is not adequate for new complex products. The in-process

manufacturing quality of components and PCBs will have to be im-

proved significantly to counteract the increased number of assem-

blies and components.

4.3.2 Example of yield calculations at the PCB

assembly level

The defect rate for new PCBs is usually calculated based on process

observations for existing PCBs. Assuming a PCB with through-hole

technology, defects are usually obtained from three sources: incoming

materials and components; assembly defects of missing, wrong, or re-

versed components; and soldering or termination defects. If it is as-

sumed that each component has 2.5 solder connections per PCB, the

quality level for multiple component PCBs can be calculated as fol-

lows, assuming reasonable PCB assembly process quality:

Solder defect rate DPU = 100 PPM

Component assembly defect rate DPU = 500 PPM

Incoming component defect rate DPU = 300 PPM

Assuming 2.5 solder connections per component, what is the total

process yield at the PCB test level for 100, 500, and 1000 component

PCBs?