Page 218 - Six Sigma for electronics design and manufacturing

P. 218

185

Six Sigma Quality and Manufacturing Costs of Electronics Products

these specifications and the defects occurring during the PCB manu-

facturing steps is not readily discernible. This has sometimes led to a

manufacturing process having a high-quality Cpk for the process

meeting its individual specifications, yet having a very poor effective

PCB assembly yield. This could result in a loss of credibility in the

Cpk values in manufacturing.

An example of such a problem is in the SMT assembly operation in

PCBs. The assembly consists of applying solder paste onto PCB com-

ponent pads through a thin metal stencil in a screening machine, then

placing the components onto the pads using an automatic placement

machine. The components remain on the PCBs because of the tacki-

ness of the solder paste. The final operation consists of passing the

PCB through a conveyer oven to reflow the solder. The solder paste

suppliers recommend a particular paste volume and height of the sol-

der deposited on the pads and a particular temperature profile for the

reflow oven. A Cpk of the solder paste and reflow operations can easi-

ly be obtained from control chart or process capability data.

High Cpk levels in solder deposition, oven profiles, and other indi-

rect measurements of quality do not necessarily lead to high yields in

PCB assembly. This has resulted in the need to develop composite

Cpk analysis based on direct defect analysis for each step of the PCB

assembly operations. These will be discussed in Chapter 8.

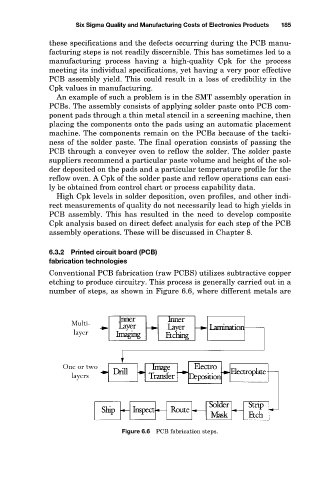

6.3.2 Printed circuit board (PCB)

fabrication technologies

Conventional PCB fabrication (raw PCBS) utilizes subtractive copper

etching to produce circuitry. This process is generally carried out in a

number of steps, as shown in Figure 6.6, where different metals are

Multi-

layer

One or two

layers

Figure 6.6 PCB fabrication steps.