Page 143 - Solid Waste Analysis and Minimization a Systems Approach

P. 143

STEP 1: ESTABLISH THE TEAM AND DEFINE THE PROJECT 121

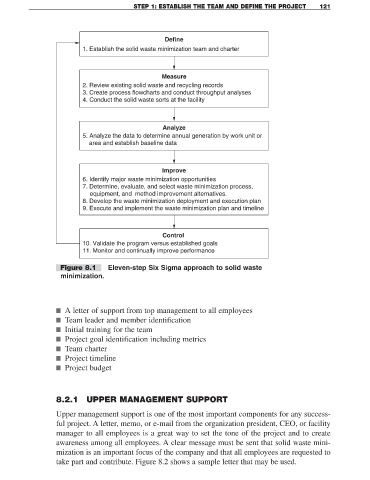

Define

1. Establish the solid waste minimization team and charter

Measure

2. Review existing solid waste and recycling records

3. Create process flowcharts and conduct throughput analyses

4. Conduct the solid waste sorts at the facility

Analyze

5. Analyze the data to determine annual generation by work unit or

area and establish baseline data

Improve

6. Identify major waste minimization opportunities

7. Determine, evaluate, and select waste minimization process,

equipment, and method improvement alternatives.

8. Develop the waste minimization deployment and execution plan

9. Execute and implement the waste minimization plan and timeline

Control

10. Validate the program versus established goals

11. Monitor and continually improve performance

Figure 8.1 Eleven-step Six Sigma approach to solid waste

minimization.

■ A letter of support from top management to all employees

■ Team leader and member identification

■ Initial training for the team

■ Project goal identification including metrics

■ Team charter

■ Project timeline

■ Project budget

8.2.1 UPPER MANAGEMENT SUPPORT

Upper management support is one of the most important components for any success-

ful project. A letter, memo, or e-mail from the organization president, CEO, or facility

manager to all employees is a great way to set the tone of the project and to create

awareness among all employees. A clear message must be sent that solid waste mini-

mization is an important focus of the company and that all employees are requested to

take part and contribute. Figure 8.2 shows a sample letter that may be used.