Page 422 - Solid Waste Analysis and Minimization a Systems Approach

P. 422

400 CHEMICAL AND PETROLEUM PROCESSING APPLICATIONS

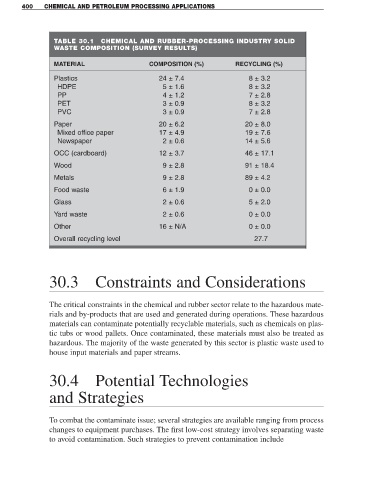

TABLE 30.1 CHEMICAL AND RUBBER-PROCESSING INDUSTRY SOLID

WASTE COMPOSITION (SURVEY RESULTS)

MATERIAL COMPOSITION (%) RECYCLING (%)

Plastics 24 ± 7.4 8 ± 3.2

HDPE 5 ± 1.6 8 ± 3.2

PP 4 ± 1.2 7 ± 2.8

PET 3 ± 0.9 8 ± 3.2

PVC 3 ± 0.9 7 ± 2.8

Paper 20 ± 6.2 20 ± 8.0

Mixed office paper 17 ± 4.9 19 ± 7.6

Newspaper 2 ± 0.6 14 ± 5.6

OCC (cardboard) 12 ± 3.7 46 ± 17.1

Wood 9 ± 2.8 91 ± 18.4

Metals 9 ± 2.8 89 ± 4.2

Food waste 6 ± 1.9 0 ± 0.0

Glass 2 ± 0.6 5 ± 2.0

Yard waste 2 ± 0.6 0 ± 0.0

Other 16 ± N/A 0 ± 0.0

Overall recycling level 27.7

30.3 Constraints and Considerations

The critical constraints in the chemical and rubber sector relate to the hazardous mate-

rials and by-products that are used and generated during operations. These hazardous

materials can contaminate potentially recyclable materials, such as chemicals on plas-

tic tubs or wood pallets. Once contaminated, these materials must also be treated as

hazardous. The majority of the waste generated by this sector is plastic waste used to

house input materials and paper streams.

30.4 Potential Technologies

and Strategies

To combat the contaminate issue; several strategies are available ranging from process

changes to equipment purchases. The first low-cost strategy involves separating waste

to avoid contamination. Such strategies to prevent contamination include