Page 164 - Steam Turbines Design, Applications, and Rerating

P. 164

144 Chapter Eight

recommends 10 percent trip speed, but for a compressor drive, 5 per-

cent could be sufficient because a maximum speed rise (instantaneous

loss of load) would never occur unless a coupling failed. In some cases,

a 5 percent trip has been used on compressor drives.

8.4 Valves

8.4.1 Single-valve turbines

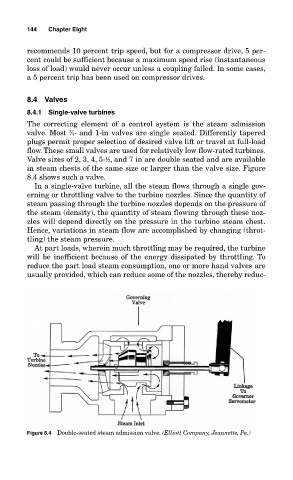

The correcting element of a control system is the steam admission

valve. Most ⁄4- and 1-in valves are single seated. Differently tapered

3

plugs permit proper selection of desired valve lift or travel at full-load

flow. These small valves are used for relatively low flow-rated turbines.

Valve sizes of 2, 3, 4, 5- ⁄2, and 7 in are double seated and are available

1

in steam chests of the same size or larger than the valve size. Figure

8.4 shows such a valve.

In a single-valve turbine, all the steam flows through a single gov-

erning or throttling valve to the turbine nozzles. Since the quantity of

steam passing through the turbine nozzles depends on the pressure of

the steam (density), the quantity of steam flowing through these noz-

zles will depend directly on the pressure in the turbine steam chest.

Hence, variations in steam flow are accomplished by changing (throt-

tling) the steam pressure.

At part loads, wherein much throttling may be required, the turbine

will be inefficient because of the energy dissipated by throttling. To

reduce the part load steam consumption, one or more hand valves are

usually provided, which can reduce some of the nozzles, thereby reduc-

Figure 8.4 Double-seated steam admission valve. (Elliott Company, Jeannette, Pa.)