Page 166 - Steam Turbines Design, Applications, and Rerating

P. 166

146 Chapter Eight

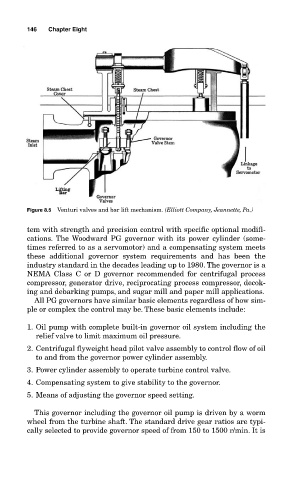

Figure 8.5 Venturi valves and bar lift mechanism. (Elliott Company, Jeannette, Pa.)

tem with strength and precision control with specific optional modifi-

cations. The Woodward PG governor with its power cylinder (some-

times referred to as a servomotor) and a compensating system meets

these additional governor system requirements and has been the

industry standard in the decades leading up to 1980. The governor is a

NEMA Class C or D governor recommended for centrifugal process

compressor, generator drive, reciprocating process compressor, decok-

ing and debarking pumps, and sugar mill and paper mill applications.

All PG governors have similar basic elements regardless of how sim-

ple or complex the control may be. These basic elements include:

1. Oil pump with complete built-in governor oil system including the

relief valve to limit maximum oil pressure.

2. Centrifugal flyweight head pilot valve assembly to control flow of oil

to and from the governor power cylinder assembly.

3. Power cylinder assembly to operate turbine control valve.

4. Compensating system to give stability to the governor.

5. Means of adjusting the governor speed setting.

This governor including the governor oil pump is driven by a worm

wheel from the turbine shaft. The standard drive gear ratios are typi-

cally selected to provide governor speed of from 150 to 1500 r/min. It is