Page 220 - Steam Turbines Design, Applications, and Rerating

P. 220

Campbell, Goodman, and SAFE Diagrams for Steam Turbine Blades 199

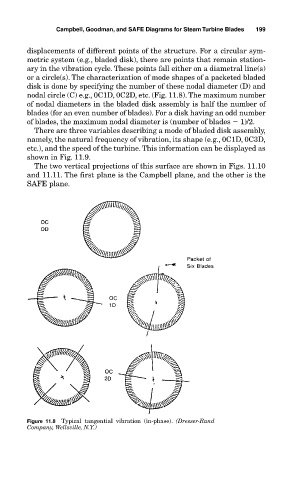

displacements of different points of the structure. For a circular sym-

metric system (e.g., bladed disk), there are points that remain station-

ary in the vibration cycle. These points fall either on a diametral line(s)

or a circle(s). The characterization of mode shapes of a packeted bladed

disk is done by specifying the number of these nodal diameter (D) and

nodal circle (C) e.g., 0C1D, 0C2D, etc. (Fig. 11.8). The maximum number

of nodal diameters in the bladed disk assembly is half the number of

blades (for an even number of blades). For a disk having an odd number

of blades, the maximum nodal diameter is (number of blades 1)/2.

There are three variables describing a mode of bladed disk assembly,

namely, the natural frequency of vibration, its shape (e.g., 0C1D, 0C3D,

etc.), and the speed of the turbine. This information can be displayed as

shown in Fig. 11.9.

The two vertical projections of this surface are shown in Figs. 11.10

and 11.11. The first plane is the Campbell plane, and the other is the

SAFE plane.

Figure 11.8 Typical tangential vibration (in-phase). (Dresser-Rand

Company, Wellsville, N.Y.)