Page 216 - Steam Turbines Design, Applications, and Rerating

P. 216

Campbell, Goodman, and SAFE Diagrams for Steam Turbine Blades 195

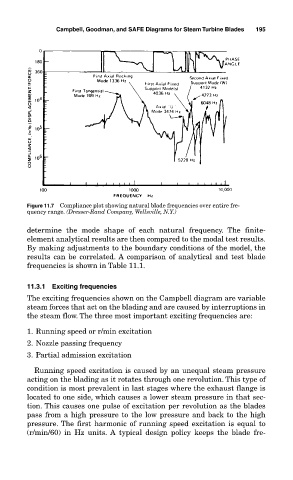

Figure 11.7 Compliance plot showing natural blade frequencies over entire fre-

quency range. (Dresser-Rand Company, Wellsville, N.Y.)

determine the mode shape of each natural frequency. The finite-

element analytical results are then compared to the modal test results.

By making adjustments to the boundary conditions of the model, the

results can be correlated. A comparison of analytical and test blade

frequencies is shown in Table 11.1.

11.3.1 Exciting frequencies

The exciting frequencies shown on the Campbell diagram are variable

steam forces that act on the blading and are caused by interruptions in

the steam flow. The three most important exciting frequencies are:

1. Running speed or r/min excitation

2. Nozzle passing frequency

3. Partial admission excitation

Running speed excitation is caused by an unequal steam pressure

acting on the blading as it rotates through one revolution. This type of

condition is most prevalent in last stages where the exhaust flange is

located to one side, which causes a lower steam pressure in that sec-

tion. This causes one pulse of excitation per revolution as the blades

pass from a high pressure to the low pressure and back to the high

pressure. The first harmonic of running speed excitation is equal to

(r/min/60) in Hz units. A typical design policy keeps the blade fre-