Page 277 - Steam Turbines Design, Applications, and Rerating

P. 277

256 Chapter Thirteen

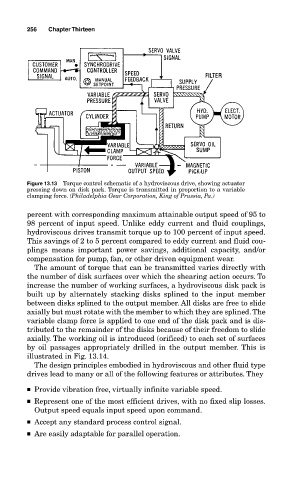

Figure 13.13 Torque control schematic of a hydroviscous drive, showing actuator

pressing down on disk pack. Torque is transmitted in proportion to a variable

clamping force. (Philadelphia Gear Corporation, King of Prussia, Pa.)

percent with corresponding maximum attainable output speed of 95 to

98 percent of input speed. Unlike eddy current and fluid couplings,

hydroviscous drives transmit torque up to 100 percent of input speed.

This savings of 2 to 5 percent compared to eddy current and fluid cou-

plings means important power savings, additional capacity, and/or

compensation for pump, fan, or other driven equipment wear.

The amount of torque that can be transmitted varies directly with

the number of disk surfaces over which the shearing action occurs. To

increase the number of working surfaces, a hydroviscous disk pack is

built up by alternately stacking disks splined to the input member

between disks splined to the output member. All disks are free to slide

axially but must rotate with the member to which they are splined. The

variable clamp force is applied to one end of the disk pack and is dis-

tributed to the remainder of the disks because of their freedom to slide

axially. The working oil is introduced (orificed) to each set of surfaces

by oil passages appropriately drilled in the output member. This is

illustrated in Fig. 13.14.

The design principles embodied in hydroviscous and other fluid type

drives lead to many or all of the following features or attributes. They

■ Provide vibration free, virtually infinite variable speed.

■ Represent one of the most efficient drives, with no fixed slip losses.

Output speed equals input speed upon command.

■ Accept any standard process control signal.

■ Are easily adaptable for parallel operation.