Page 275 - Steam Turbines Design, Applications, and Rerating

P. 275

254 Chapter Thirteen

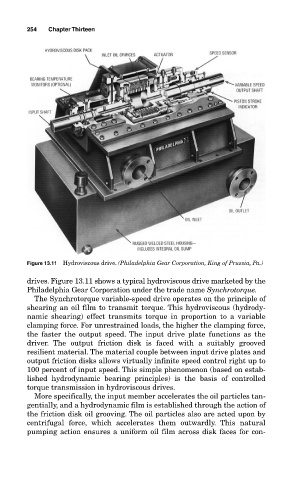

Figure 13.11 Hydroviscous drive. (Philadelphia Gear Corporation, King of Prussia, Pa.)

drives. Figure 13.11 shows a typical hydroviscous drive marketed by the

Philadelphia Gear Corporation under the trade name Synchrotorque.

The Synchrotorque variable-speed drive operates on the principle of

shearing an oil film to transmit torque. This hydroviscous (hydrody-

namic shearing) effect transmits torque in proportion to a variable

clamping force. For unrestrained loads, the higher the clamping force,

the faster the output speed. The input drive plate functions as the

driver. The output friction disk is faced with a suitably grooved

resilient material. The material couple between input drive plates and

output friction disks allows virtually infinite speed control right up to

100 percent of input speed. This simple phenomenon (based on estab-

lished hydrodynamic bearing principles) is the basis of controlled

torque transmission in hydroviscous drives.

More specifically, the input member accelerates the oil particles tan-

gentially, and a hydrodynamic film is established through the action of

the friction disk oil grooving. The oil particles also are acted upon by

centrifugal force, which accelerates them outwardly. This natural

pumping action ensures a uniform oil film across disk faces for con-