Page 67 - Steam Turbines Design, Applications, and Rerating

P. 67

48 Chapter Two

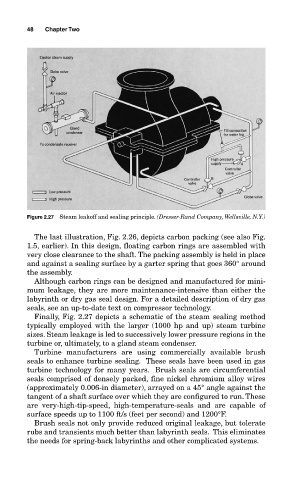

Figure 2.27 Steam leakoff and sealing principle. (Dresser-Rand Company, Wellsville, N.Y.)

The last illustration, Fig. 2.26, depicts carbon packing (see also Fig.

1.5, earlier). In this design, floating carbon rings are assembled with

very close clearance to the shaft. The packing assembly is held in place

and against a sealing surface by a garter spring that goes 360° around

the assembly.

Although carbon rings can be designed and manufactured for mini-

mum leakage, they are more maintenance-intensive than either the

labyrinth or dry gas seal design. For a detailed description of dry gas

seals, see an up-to-date text on compressor technology.

Finally, Fig. 2.27 depicts a schematic of the steam sealing method

typically employed with the larger (1000 hp and up) steam turbine

sizes. Steam leakage is led to successively lower pressure regions in the

turbine or, ultimately, to a gland steam condenser.

Turbine manufacturers are using commercially available brush

seals to enhance turbine sealing. These seals have been used in gas

turbine technology for many years. Brush seals are circumferential

seals comprised of densely packed, fine nickel chromium alloy wires

(approximately 0.006-in diameter), arrayed on a 45° angle against the

tangent of a shaft surface over which they are configured to run. These

are very-high-tip-speed, high-temperature-seals and are capable of

surface speeds up to 1100 ft/s (feet per second) and 1200°F.

Brush seals not only provide reduced original leakage, but tolerate

rubs and transients much better than labyrinth seals. This eliminates

the needs for spring-back labyrinths and other complicated systems.