Page 95 - Steam Turbines Design, Applications, and Rerating

P. 95

76 Chapter Three

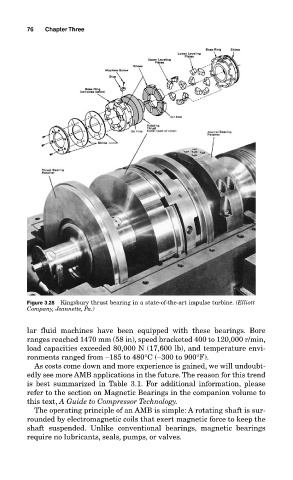

Figure 3.28 Kingsbury thrust bearing in a state-of-the-art impulse turbine. (Elliott

Company, Jeannette, Pa.)

lar fluid machines have been equipped with these bearings. Bore

ranges reached 1470 mm (58 in), speed bracketed 400 to 120,000 r/min,

load capacities exceeded 80,000 N (17,600 lb), and temperature envi-

ronments ranged from −185 to 480°C (−300 to 900°F).

As costs come down and more experience is gained, we will undoubt-

edly see more AMB applications in the future. The reason for this trend

is best summarized in Table 3.1. For additional information, please

refer to the section on Magnetic Bearings in the companion volume to

this text, A Guide to Compressor Technology.

The operating principle of an AMB is simple: A rotating shaft is sur-

rounded by electromagnetic coils that exert magnetic force to keep the

shaft suspended. Unlike conventional bearings, magnetic bearings

require no lubricants, seals, pumps, or valves.