Page 93 - Steam Turbines Design, Applications, and Rerating

P. 93

74 Chapter Three

loaded side), so that the hydrodynamic forces and thereby the frictional

forces decrease on this side.

A thrust bearing can be monitored satisfactorily only by temperature

sensors (thermocouple, resistance thermometer) near the babbitt lining

in the area of highest oil film temperatures. A thermometer in the oil

discharge of the thrust bearing cannot indicate overheating of a bearing

pad, because the additional friction heat generated by the endangered

pad is so small in relation to the total friction heat of the thrust bearing

that temperature rise in the early stages of incipient bearing failure is

not likely to be detected. A thermometer in the oil discharge can only

monitor the bulk oil supply temperature of the thrust bearing.

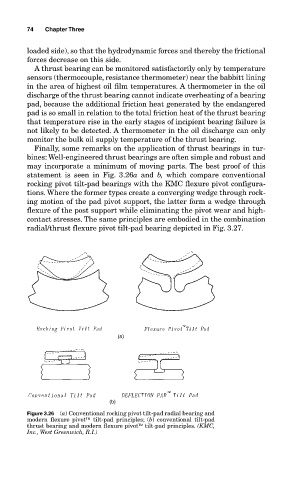

Finally, some remarks on the application of thrust bearings in tur-

bines: Well-engineered thrust bearings are often simple and robust and

may incorporate a minimum of moving parts. The best proof of this

statement is seen in Fig. 3.26a and b, which compare conventional

rocking pivot tilt-pad bearings with the KMC flexure pivot configura-

tions. Where the former types create a converging wedge through rock-

ing motion of the pad pivot support, the latter form a wedge through

flexure of the post support while eliminating the pivot wear and high-

contact stresses. The same principles are embodied in the combination

radial/thrust flexure pivot tilt-pad bearing depicted in Fig. 3.27.

(a)

(b)

Figure 3.26 (a) Conventional rocking pivot tilt-pad radial bearing and

modern flexure pivot™ tilt-pad principles; (b) conventional tilt-pad

thrust bearing and modern flexure pivot™ tilt-pad principles. (KMC,

Inc., West Greenwich, R.I.)