Page 89 - Steam Turbines Design, Applications, and Rerating

P. 89

70 Chapter Three

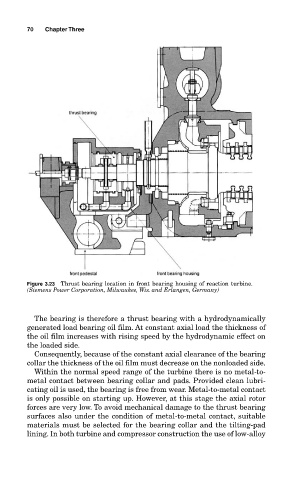

Figure 3.23 Thrust bearing location in front bearing housing of reaction turbine.

(Siemens Power Corporation, Milwaukee, Wis. and Erlangen, Germany)

The bearing is therefore a thrust bearing with a hydrodynamically

generated load bearing oil film. At constant axial load the thickness of

the oil film increases with rising speed by the hydrodynamic effect on

the loaded side.

Consequently, because of the constant axial clearance of the bearing

collar the thickness of the oil film must decrease on the nonloaded side.

Within the normal speed range of the turbine there is no metal-to-

metal contact between bearing collar and pads. Provided clean lubri-

cating oil is used, the bearing is free from wear. Metal-to-metal contact

is only possible on starting up. However, at this stage the axial rotor

forces are very low. To avoid mechanical damage to the thrust bearing

surfaces also under the condition of metal-to-metal contact, suitable

materials must be selected for the bearing collar and the tilting-pad

lining. In both turbine and compressor construction the use of low-alloy