Page 86 - Steam Turbines Design, Applications, and Rerating

P. 86

Bearings for Mechanical Drive Turbines 67

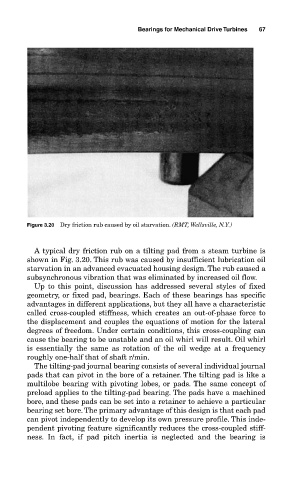

Figure 3.20 Dry friction rub caused by oil starvation. (RMT, Wellsville, N.Y.)

A typical dry friction rub on a tilting pad from a steam turbine is

shown in Fig. 3.20. This rub was caused by insufficient lubrication oil

starvation in an advanced evacuated housing design. The rub caused a

subsynchronous vibration that was eliminated by increased oil flow.

Up to this point, discussion has addressed several styles of fixed

geometry, or fixed pad, bearings. Each of these bearings has specific

advantages in different applications, but they all have a characteristic

called cross-coupled stiffness, which creates an out-of-phase force to

the displacement and couples the equations of motion for the lateral

degrees of freedom. Under certain conditions, this cross-coupling can

cause the bearing to be unstable and an oil whirl will result. Oil whirl

is essentially the same as rotation of the oil wedge at a frequency

roughly one-half that of shaft r/min.

The tilting-pad journal bearing consists of several individual journal

pads that can pivot in the bore of a retainer. The tilting pad is like a

multilobe bearing with pivoting lobes, or pads. The same concept of

preload applies to the tilting-pad bearing. The pads have a machined

bore, and these pads can be set into a retainer to achieve a particular

bearing set bore. The primary advantage of this design is that each pad

can pivot independently to develop its own pressure profile. This inde-

pendent pivoting feature significantly reduces the cross-coupled stiff-

ness. In fact, if pad pitch inertia is neglected and the bearing is