Page 83 - Steam Turbines Design, Applications, and Rerating

P. 83

64 Chapter Three

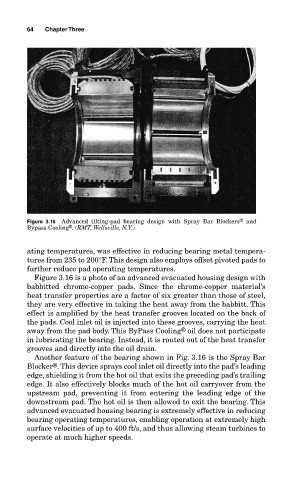

Figure 3.16 Advanced tilting-pad bearing design with Spray Bar Blockers ® and

Bypass Cooling ® . (RMT, Wellsville, N.Y.)

ating temperatures, was effective in reducing bearing metal tempera-

tures from 235 to 200°F. This design also employs offset pivoted pads to

further reduce pad operating temperatures.

Figure 3.16 is a photo of an advanced evacuated housing design with

babbitted chrome-copper pads. Since the chrome-copper material’s

heat transfer properties are a factor of six greater than those of steel,

they are very effective in taking the heat away from the babbitt. This

effect is amplified by the heat transfer grooves located on the back of

the pads. Cool inlet oil is injected into these grooves, carrying the heat

away from the pad body. This ByPass Cooling ® oil does not participate

in lubricating the bearing. Instead, it is routed out of the heat transfer

grooves and directly into the oil drain.

Another feature of the bearing shown in Fig. 3.16 is the Spray Bar

Blocker . This device sprays cool inlet oil directly into the pad’s leading

®

edge, shielding it from the hot oil that exits the preceding pad’s trailing

edge. It also effectively blocks much of the hot oil carryover from the

upstream pad, preventing it from entering the leading edge of the

downstream pad. The hot oil is then allowed to exit the bearing. This

advanced evacuated housing bearing is extremely effective in reducing

bearing operating temperatures, enabling operation at extremely high

surface velocities of up to 400 ft/s, and thus allowing steam turbines to

operate at much higher speeds.