Page 82 - Steam Turbines Design, Applications, and Rerating

P. 82

Bearings for Mechanical Drive Turbines 63

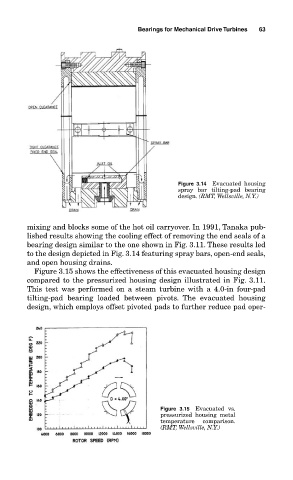

Figure 3.14 Evacuated housing

spray bar tilting-pad bearing

design. (RMT, Wellsville, N.Y.)

mixing and blocks some of the hot oil carryover. In 1991, Tanaka pub-

lished results showing the cooling effect of removing the end seals of a

bearing design similar to the one shown in Fig. 3.11. These results led

to the design depicted in Fig. 3.14 featuring spray bars, open-end seals,

and open housing drains.

Figure 3.15 shows the effectiveness of this evacuated housing design

compared to the pressurized housing design illustrated in Fig. 3.11.

This test was performed on a steam turbine with a 4.0-in four-pad

tilting-pad bearing loaded between pivots. The evacuated housing

design, which employs offset pivoted pads to further reduce pad oper-

Figure 3.15 Evacuated vs.

pressurized housing metal

temperature comparison.

(RMT, Wellsville, N.Y.)