Page 77 - Steam Turbines Design, Applications, and Rerating

P. 77

58 Chapter Three

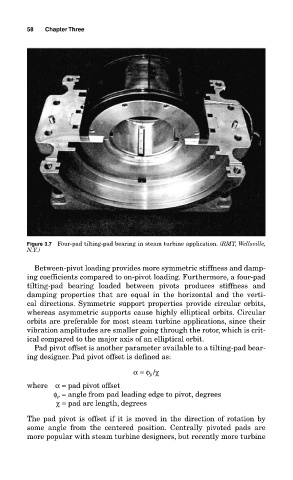

Figure 3.7 Four-pad tilting-pad bearing in steam turbine application. (RMT, Wellsville,

N.Y.)

Between-pivot loading provides more symmetric stiffness and damp-

ing coefficients compared to on-pivot loading. Furthermore, a four-pad

tilting-pad bearing loaded between pivots produces stiffness and

damping properties that are equal in the horizontal and the verti-

cal directions. Symmetric support properties provide circular orbits,

whereas asymmetric supports cause highly elliptical orbits. Circular

orbits are preferable for most steam turbine applications, since their

vibration amplitudes are smaller going through the rotor, which is crit-

ical compared to the major axis of an elliptical orbit.

Pad pivot offset is another parameter available to a tilting-pad bear-

ing designer. Pad pivot offset is defined as:

α=φ p /χ

where α= pad pivot offset

φ p = angle from pad leading edge to pivot, degrees

χ= pad arc length, degrees

The pad pivot is offset if it is moved in the direction of rotation by

some angle from the centered position. Centrally pivoted pads are

more popular with steam turbine designers, but recently more turbine