Page 80 - Steam Turbines Design, Applications, and Rerating

P. 80

Bearings for Mechanical Drive Turbines 61

bearing damping and decreasing bearing stiffness. For this reason,

tilting-pad bearing L/D ratios have increased in recent years from a

standard of 0.5 to 0.75.

3.1.3 Advanced tilting-pad journal bearings

In recent years, the focus of tilting-pad bearing designers has been on

reduced-temperature designs. This has been driven partly by the strin-

gent rotor dynamic specifications that steam turbine manufacturers

must adhere to in order to sell their rotating equipment. Large journal

diameters result in less severe critical speeds. However, larger-diameter

journals result in high surface velocities, often exceeding 90 m/s (300

ft/s). Furthermore, for increased efficiencies, steam turbines are required

to run at even higher speeds, again increasing surface velocity. At these

high surface speeds, special care must be taken to cool the bearing.

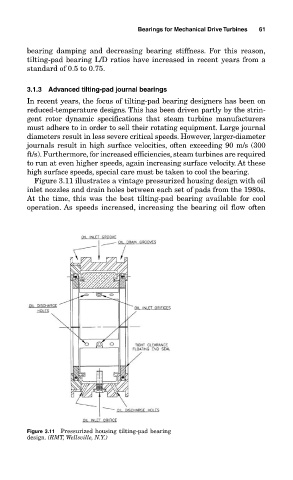

Figure 3.11 illustrates a vintage pressurized housing design with oil

inlet nozzles and drain holes between each set of pads from the 1980s.

At the time, this was the best tilting-pad bearing available for cool

operation. As speeds increased, increasing the bearing oil flow often

Figure 3.11 Pressurized housing tilting-pad bearing

design. (RMT, Wellsville, N.Y.)