Page 84 - Steam Turbines Design, Applications, and Rerating

P. 84

Bearings for Mechanical Drive Turbines 65

3.1.4 Lubrication-starved

tilting-pad bearings

While the advanced tilting-pad bearing designs with evacuated hous-

ings have been successful in reducing the operating temperature of the

pad by 10 to 20 percent, care must be taken when implementing the

design. The wide-open end seals and housing drains result in low hous-

ing cavity pressures, often below 1.0 psig. Conversely, conventional

flooded housing designs have typical housing pressures that range

from 5 to 15 psig for a 20-psig oil inlet. These low housing pressures

can lead to oil starvation and subsynchronous vibration if improperly

applied.

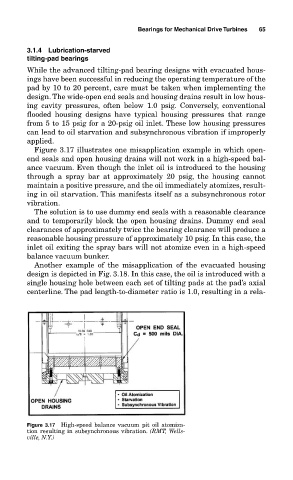

Figure 3.17 illustrates one misapplication example in which open-

end seals and open housing drains will not work in a high-speed bal-

ance vacuum. Even though the inlet oil is introduced to the housing

through a spray bar at approximately 20 psig, the housing cannot

maintain a positive pressure, and the oil immediately atomizes, result-

ing in oil starvation. This manifests itself as a subsynchronous rotor

vibration.

The solution is to use dummy end seals with a reasonable clearance

and to temporarily block the open housing drains. Dummy end seal

clearances of approximately twice the bearing clearance will produce a

reasonable housing pressure of approximately 10 psig. In this case, the

inlet oil exiting the spray bars will not atomize even in a high-speed

balance vacuum bunker.

Another example of the misapplication of the evacuated housing

design is depicted in Fig. 3.18. In this case, the oil is introduced with a

single housing hole between each set of tilting pads at the pad’s axial

centerline. The pad length-to-diameter ratio is 1.0, resulting in a rela-

Figure 3.17 High-speed balance vacuum pit oil atomiza-

tion resulting in subsynchronous vibration. (RMT, Wells-

ville, N.Y.)