Page 92 - Structural Steel Designers Handbook AISC, AASHTO, AISI, ASTM, and ASCE-07 Design Standards

P. 92

Brockenbrough_Ch03.qxd 9/29/05 5:05 PM Page 3.24

CONNECTIONS

3.24 CHAPTER THREE

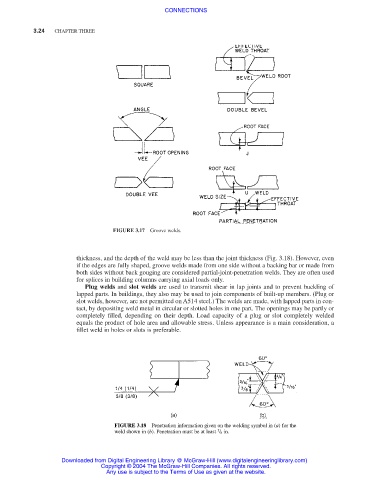

FIGURE 3.17 Groove welds.

thickness, and the depth of the weld may be less than the joint thickness (Fig. 3.18). However, even

if the edges are fully shaped, groove welds made from one side without a backing bar or made from

both sides without back gouging are considered partial-joint-penetration welds. They are often used

for splices in building columns carrying axial loads only.

Plug welds and slot welds are used to transmit shear in lap joints and to prevent buckling of

lapped parts. In buildings, they also may be used to join components of built-up members. (Plug or

slot welds, however, are not permitted on A514 steel.) The welds are made, with lapped parts in con-

tact, by depositing weld metal in circular or slotted holes in one part. The openings may be partly or

completely filled, depending on their depth. Load capacity of a plug or slot completely welded

equals the product of hole area and allowable stress. Unless appearance is a main consideration, a

fillet weld in holes or slots is preferable.

FIGURE 3.18 Penetration information given on the welding symbol in (a) for the

5

weld shown in (b). Penetration must be at least / 8 in.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.